5.1: Introduction to Fire Protection and Prevention

- Page ID

- 18137

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Fire

Each year approximately 5,000 people lose their lives as the result of fire. OSHA estimates that nearly 10% of those deaths can be attributed to workplace fires. Subpart F of the 1926 Construction Standards is designed to protect workers from the hazards associated with fires in the workplace, but specifically for construction sites and construction work. Subpart F contains requirements for workplace firefighting equipment, fire exits, workplace fire emergency and prevention plans, employee training and the proper handling and storage of flammable and combustible liquids.

Subpart E and Subpart L of the General Industry Standard focus on emergency egress and emergency planning while also providing National Fire Protection Association(NFPA) requirements embedded in building and safety code. As a result construction, maritime, and agriculture are excluded from the requirements of this standard.

The Science of Fire - Fire Types

General

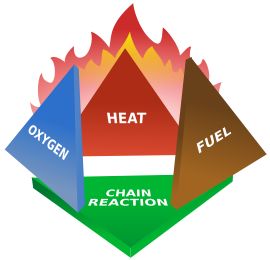

The classic fire triangle has been used for years to represent the three elements necessary for the occurrence of a fire: Heat, Fuel and Oxygen. Recently, a fire tetrahedron, a four-sided figure, has replaced the triangle (see Figure 5.1.1). The fourth side is chemical reaction and represents a chemical chain reaction that occurs in the burning of flammable or combustible liquids and flammable gases. Each of the sides represents one of four ways to extinguish a fire.

Removing the heat from the fire, such as by adding water or other chemicals can extinguish the fire. Somewhat more difficult is removing the fuel from the fire, such as for liquid storage tank fires. The oxygen can be removed from the fire by smothering the fire and the chemical reaction of the fire can be interrupted, stopping the growth of the fire.

The Fire Tetrahedron

Fire classification

Fires are classified as Class A, B, C, D and K fires.

Class A Fires

Class A fires occur in ordinary materials, such as, wood, paper and rags. The use of water or water-based solutions is most successful in extinguishing these types of fires.

Class B Fires

Class B fires occur in the vapor-air mixture over the surface of flammable liquids, such as, gasoline, oil, grease and paint thinners. The most successful way to extinguish these fires is by limiting the oxygen or interrupting the chemical chain reaction. Solid streams of water are likely to spread the fire, but in some cases a water fog nozzle with a fine mist may prove effective. Generally, dry, multi-purpose chemicals or foams are used to extinguish these fires.

Class C Fires

Class C fires occur in or near electrical equipment. Non-conducting agents, such as dry- chemical, carbon dioxide and halogenated extinguishing agents are commonly used to extinguish Class C fires. Foam or streams of water should not be used because they are good conductors.

Class D Fires

There is also a Class D fire, but these fires are not frequently encountered in construction. These fires occur in combustible metals, such as magnesium, titanium, sodium, etc.

Specialized techniques and equipment must be used to control and extinguish these types of fires. Normal extinguishing agents should not be used because they may increase the intensity of the fire.

Class K Fires

Class K fires involve vegetable oils, animal oils, or fats in cooking appliances. Extinguishers with a K rating are designed to extinguish fires involving vegetable oils, animal oils, or fats utilized in commercial cooking appliances.

Portable fire extinguishers

Firefighting equipment, such as portable fire extinguishers, shall be suitable for the Class of fire in which it is to be used. Class A fire extinguishers are identifiable by a triangle which contains the letter "A" and if colored, by the color green. Class B fire extinguishers are identifiable by a square which contains the letter "B" and if colored, by the color red. Class C fire extinguishers are identifiable by a circle which contains the letter "C" and if colored, by the color blue.

Fire Protection

Employer responsibility

The employer shall be responsible for the development of a fire protection program to be followed throughout all phases of the construction and demolition work. In addition, the employer shall provide for the firefighting equipment as specified in this subpart. As fire hazards occur, there shall be no delay in providing the necessary equipment.

As warranted by the project, the employer shall provide a trained and equipped firefighting organization (Fire Brigade) to assure adequate protection to life.

Firefighting equipment accessibility

Access to all available firefighting equipment shall be maintained at all times. All firefighting equipment, provided by the employer, shall be conspicuously located. All firefighting equipment shall be periodically inspected and maintained in operating condition. Defective equipment shall be immediately replaced.

Water supply

A temporary or permanent water supply, of sufficient volume, duration, and pressure, required to properly operate the firefighting equipment shall be made available as soon as combustible materials accumulate. Where underground water mains are to be provided, they shall be installed, completed, and made available for use as soon as practicable.

Site fire extinguisher requirements

A fire extinguisher, rated not less than 2A, shall be provided for each 3,000 square feet of the protected building area, or major fraction thereof. Travel distance from any point of the protected area to the nearest fire extinguisher shall not exceed 100 feet. One 55-gallon open drum of water with two fire pails may be substituted for a fire extinguisher having a 2A rating.

One or more fire extinguishers, rated not less than 2A, shall be provided on each floor. In multistory buildings, at least one fire extinguisher shall be located adjacent to the stairway. Extinguishers and water drums, subject to freezing, shall be protected from freezing.

Fire extinguisher ratings

Fire extinguisher ratings refer to the relative effectiveness of the fire extinguisher to one gallon of water. A 2A fire extinguisher is therefore twice as effective as one gallon of water or as effective as two gallons of water on an ordinary combustible materials fire (Class A fire). A 1/2-inch diameter garden-type hose line, not to exceed 100 feet in length and equipped with a nozzle, may be substituted for a 2A-rated fire extinguisher, provided it is capable of discharging a minimum of five gallons per minute with a minimum hose stream range of 30 feet horizontally. The garden-type hose lines shall be mounted on conventional racks or reels. The number and location of hose racks or reels shall be such that at least one hose stream can be applied to all points in the area. Capacity of extinguishers shall be in accordance with ANSI/UL711,”Rating and Fire Testing of Extinguishers”.

Flammable or combustible liquids

A fire extinguisher, rated not less than 10B, shall be provided within 50 feet of wherever more than 5 gallons of flammable or combustible liquids or 5 pounds of flammable gas are being used on the jobsite. This requirement does not apply to the integral fuel tanks of motor vehicles.

Inspection and maintenance

Portable fire extinguishers shall be inspected periodically and maintained in good working condition. The employer shall assure that portable fire extinguishers are maintained in a fully charged and operable condition and kept in their designated places at all times except during use.

The employer shall assure that portable fire extinguishers are subjected to an annual maintenance check. Stored pressure extinguishers do not require an internal examination. The employer shall record the annual maintenance date and retain this record for one year after the last entry or the life of the shell, whichever is less.

Fire extinguishers equipment approval

Fire extinguishers, which have been listed or approved by a nationally recognized testing laboratory, shall be used to meet the requirements of Subpart F.

Training

Where the employer has provided portable fire extinguishers for employee use in the workplace, the employer shall also provide an educational program to familiarize employees with the general principles of fire extinguisher use and the hazards involved with incipient stage firefighting. Training shall occur upon initial employment and at least annually thereafter.

Demolition or alterations

During demolition or alterations, existing automatic sprinkler installations shall be retained in service as long as reasonable. The operation of sprinkler control valves shall be permitted only by properly authorized persons. Modification of sprinkler systems to permit alterations or additional demolition should be expedited so that the automatic protection may be returned to service as quickly as possible. Sprinkler control valves shall be checked daily at close of work to ascertain that the protection is in service.

Emergency notification

An alarm system, e.g., telephone system, siren, etc., shall be established by the employer whereby employees on the site and the local fire department can be alerted for an emergency. The alarm code and reporting instructions shall be conspicuously posted at phones and at employee entrances.

Fire Prevention

General

Smoking shall be prohibited at, or in, the vicinity of operations, which constitute a fire hazard, and shall be conspicuously posted: "No Smoking or Open Flame."

Portable fire extinguishing equipment

Portable fire extinguishing equipment, suitable for the fire hazard involved shall be provided at convenient, conspicuously accessible locations in the yard area. Portable fire extinguishers, rated not less than 2A, shall be placed so that maximum travel distance to the nearest unit shall not exceed 100 feet.

Materials stored outdoors

Combustible materials installed in open yard storage areas shall be piled with due regard to the stability of piles and in no case higher than 20 feet. Method of piling shall be solid wherever possible and in orderly and regular piles. No combustible material shall be stored outdoors within 10 feet of a building or structure.

Materials stored indoors

Storage in indoor areas shall not obstruct, or adversely affect, means of exit. All materials shall be stored, handled, and piled with due regard to their fire characteristics. Incompatible materials, which may create a fire hazard, shall be segregated by a barrier having a fire resistance of at least one hour.

Material stored indoors shall be piled to minimize the spread of fire internally and to permit convenient access for firefighting. Stable piling shall be maintained at all times. Aisle space shall be maintained to safely accommodate the widest vehicle that may be used within the building for firefighting purposes.

A clearance of 24 inches shall be maintained around the path of travel of fire doors unless a barricade is provided, in which case no clearance is needed. Material shall not be stored within 36 inches of a fire door opening.

Clearance shall be maintained around lights and heating units to prevent ignition of combustible materials. Clearance of at least 36 inches shall be maintained between the top level of the stored material and the sprinkler deflectors.

Flammable and Combustible Liquids

General

Only approved containers and portable tanks shall be used for storage and handling of flammable and combustible liquids. Approved metal safety cans shall be used for the handling and use of flammable liquids in quantities greater than one gallon, except that this shall not apply to those flammable liquid materials, which are highly viscous (extremely hard to pour), which may be used and handled in original shipping containers. For quantities of one gallon or less, only the original container or approved metal safety cans shall be used for storage, use, and handling of flammable liquids.

Storage

No more than 25 gallons of flammable or combustible liquids shall be stored in a room outside of an approved storage cabinet. Electrical wiring and equipment located in inside storage rooms shall be approved for Class 1, Division 1, Hazardous Locations.

Flammable or combustible liquids shall not be stored in areas used for exits, stairways, or normally used for the safe passage of people. Materials which will react with water and create a fire hazard shall not be stored in the same room with flammable or combustible liquids.

In locations where flammable vapors may be present, precautions shall be taken to prevent ignition by eliminating or controlling sources of ignition. Sources of ignition may include open flames, lightning, smoking, cutting and welding, hot surfaces, frictional heat, sparks (static, electrical, and mechanical), spontaneous ignition, chemical and physical-chemical reactions, and radiant heat.

Equipment in classified (Class I, Class II, Class III) hazardous locations must also be suitable for those locations and not permit the ignition of vapors, gases, or combustible dusts.

Fire Protection and Prevention – Definitions

Approved for the purpose of this subpart: Equipment that has been listed or approved by a nationally recognized testing laboratory (NRTL) such as Factory Mutual Engineering Corp., or Underwriters' Laboratories, Inc. or Federal agencies such as Bureau of Mines, or U.S. Coast Guard, which issues approvals for such equipment.

Combustible liquids: Any liquid having a flash point at or above 140° F (60°C), and below 200° F (93.4°C).

Flammable liquids: Any liquid having a flash point below 140° F. and having a vapor pressure not exceeding 40 pounds per square inch (absolute) at 100° F.

Flash point: The temperature at which it gives off vapor sufficient to form an ignitable mixture with the air near the surface of the liquid or within the vessel used as determined by appropriate test procedure and apparatus.

Ignition temperature: The minimum temperature required to initiate or cause self-sustained combustion. The ignition temperature of some common materials is listed below:

| Material | Ignition Temperature |

|---|---|

| Newspaper | 446°F |

| Cotton Batton | 450°F |

| Gasoline | 500° - 850°F |

| Sawdust | 400° - 500°F |

Lower explosive limit (LEL): The minimum concentration of vapor in air or oxygen below which propagation of flame does not occur on contact with a source of ignition.

Safety can: An approved closed container, of not more than 5 gallons capacity, having a flash-arresting screen, spring-closing lid and spout cover and so designed that it will safely relieve internal pressure when subjected to fire exposure. Plastic containers can be used provided they are "approved."

Upper explosive limit (UEL): The maximum concentration in air or oxygen below which propagation of flame does not occur on contact with a source of ignition.

Electrical Bonding: The practice of intentionally electrically connecting all exposed metal items not designed to carry electricity in a room or building as protection from electric shock and to protect against static charge build up.

Electrical Grounding: To ensure that persons in the area are not exposed to dangerous, electric-shock voltage. To provide current-carrying capability that can accept ground-fault current without creating a fire or explosive hazard.