4.5: Faucets, Fixtures, and Fixture Drains

- Page ID

- 2322

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Plumbing codes require that every house must have at least one toilet, lavatory sink, bathtub or shower, and a kitchen sink. These, and some other items referred to in this chapter, are known as fixtures. Clearances from finished walls and other fixtures are strictly regulated by code and most fixtures are provided with a manufacturer rough-in sheet and installation instructions. Codes regulate the materials that are used to manufacture plumbing fixtures, which must have smooth, impervious surfaces and be defect free. Fixtures that incorporate porcelain enameled surfaces must be capable of withstanding acid without damaging the fixture.

Pay attention to flow rates, volume, and water usage in selecting fixtures. One key aspect of sustainability in plumbing focuses on water conservation. Lavatory faucets and shower heads are two primary focal points of conserving water. The true water saving aspect of a shower is based on duration of each use. A handheld shower can be equipped with mechanisms to turn off the water flow for certain showering activities, such as lathering.

Faucets

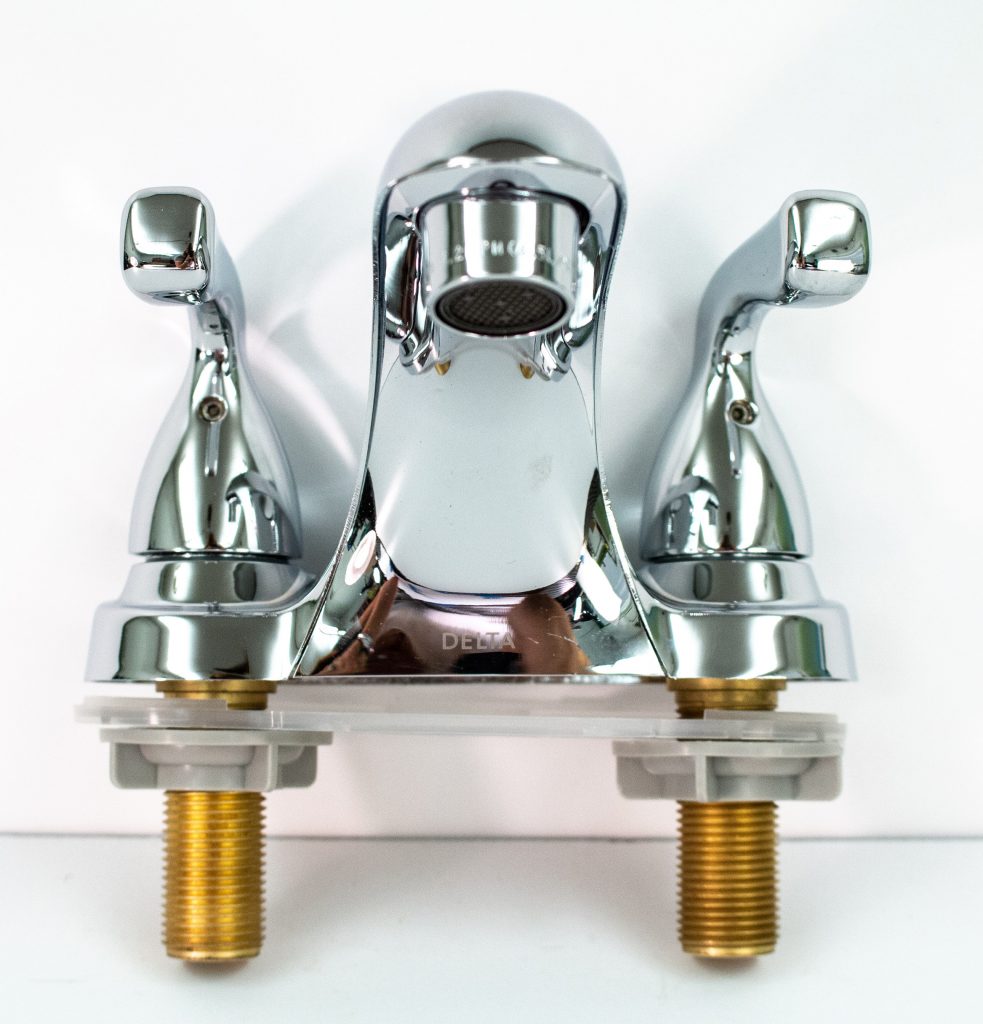

Lavatory with 2 handles by Gwen Arkin is licensed under CC BY 4.0

Selecting which manufacturer’s product to install is based on cost, quality, and preferred faucet design which includes aesthetics, and functionality. Most master bathrooms and guest bathrooms have more expensive finishes than other bathrooms in a large house. Faucet finishes dictate the finishes used for drain assemblies and bathroom accessories which creates a color theme. Faucet accessories are available to create various themes. Water conservation faucets have aerators that reduce the flow of water to allow only 0.5 gallons per minute as opposed to a 1.0 gallons per minute. Single-handle faucets blend the hot and cold water with the use of one handle; two-handle designs require a user to operate both handles to achieve a desired temperature.

| Fixture | Single Handle | Two Handle | Three Handle |

|---|---|---|---|

| Bathtub | Yes | Yes | No |

| Bidet | No | Yes | No |

| Kitchen Sink | Yes | Yes | No |

| Large Capacity or Garden Tub | No | Yes | No |

| Laundry Sink | No | Yes | No |

| Lavatory Sink | Yes | Yes | No |

| Shower | Yes | Yes | No |

| Tub & Shower | Yes | Yes | *Yes |

Faucet Installation

A faucet installed on a sink through a countertop or through a tub platform, instead of through the fixture itself, is considered a deck mounted faucet. All faucets must be designed to prevent backflow of wastewater into the water distribution system and plumbing codes require that a faucet have an air gap or be protected with a vacuum breaker or approved check valve. Most faucets use a tightening nut and flat washer to secure the faucet to a fixture. A bathtub and shower faucet is usually installed during the rough-in phase of construction.

Faucet Water Supply:Connecting a water supply pipe to a faucet varies with the type of faucet and can be accomplished with many common connection methods. Some faucets connect to the water supply with male or female adapters to create a soldered connection, and others use a specially designed 3/8” OD supply tube that connects to the male threads of a faucet.

| Fixture | Male Thread | Female Thread | Solder | 3/8 Tubing |

|---|---|---|---|---|

| Bathtub | Yes | Yes | Yes | No |

| Bidet | Yes | No | No | Yes |

| Kitchen | Yes | No | No | Yes |

| Large Capacity or Whirlpool Tub | Yes | No | No | No |

| Laundry | Yes | No | No | No |

| Lavatory | Yes | No | No | Yes |

| Shower | Yes | Yes | Yes | No |

| Tub & Shower | Yes | Yes | Yes | No |

Drain Assemblies

Drain assemblies are purchased based on the specific fixture they serve. Codes dictate the minimum drain size serving a particular fixture, and all fixtures and drain assemblies are manufactured based on minimum code requirements. A trap adapter is installed to connect the stubout pipe to the p-trap outlet. Most codes dictate that the largest size foreign object that can enter a drainage system is 1/2” diameter.

Fixture Types and Assemblies

Toilet

Toilets are also known as water closets. Residential toilets must be self-cleaning during their flushing cycle and have a toilet seat installed. Water conservation fixtures ate rated at 1.6 gallons per flush (gpf) and 1.28 gpf. The most common residential toilet bowl design uses a siphon-jet flushing action. A tank handle activates a flushing cycle, and the water flows from the tank and enters the rim of the bowl. Small holes in the rim are angled to allow the water to create the vortex. The vortex (swirl) begins a siphoning action to evacuate waste from the bowl. The jet stream exits the rim and thrusts into the passageway of the toilet providing the initial thrust in the flushing process.

The water supply is located on the left side of all toilets. The stop and escutcheon are installed the same for a toilet as for other fixtures. The water is connected to a toilet using a a tank supply. A tank supply is a chrome-plated soft copper tubing having a flat end that connects the stop to the fill valve. More modern supply lines are compression fit, plastic tube, with some having a braided stainless steel sleeve that protects the line from swelling and bursting. The toilet is installed onto the closet (toilet) flange and sealed with a wax ring. Some wax seals have a plastic accessory called a horn molded into the wax.

Toilet ADA Requirements: Handicap fixtures must comply with the Americans with Disabilities Act (ADA). The tank handle of an ADA-compliant toilet must be located on the side of the tank that has the greatest distance from a sidewall. A handle located on the top of a tank typically meets ADA handle location regulations. The height of a toilet bowl from the floor, which includes the seat, is regulated by code. ADA codes dictate that the minimum height from a floor to a toilet seat is 16-1/2”; the maximum is 19-1/2”.

Toilet Piping Locations: The outlet distance of a standard toilet is 12” from the finished wall located behind the toilet (back wall). Lesser used 10” and 14” rough toilets are available in some toilet designs. Typically, one-piece toilets have different water rough-in location requirements than two-piece toilets. When selecting a one-piece toilet, always request the manufacturer’s data sheet, known as a roughin sheet, to confirm the water and drain pipes’ installation locations.

Toilet Bowl Shapes & Seats: Residential toilets have round style bowls. Elongated bowls installed in many homes are usually considered a fixture upgrade. Codes require that an elongated (oval) bowl design be installed in commercial applications. When selecting an elongated bowl in place of a round bowl, be sure to check your local codes pertaining to the

minimum clearance in front of a toilet. Codes require that commercial seats be an open front type and not have a lid.

How To Replace and Install a Toilet

Query \(\PageIndex{1}\)

Fixing a Noisy Toilet & Other Problems with Fluidmaster

Query \(\PageIndex{2}\)

Lavatory sink

Also known as a lavatory, lav, or basin. Many types, shapes, and colors are available. Many homebuilders install cultured marble solid surface countertops with pre-molded sink basins, so the plumber does not install a separate sink. Other models of lavatory sinks include drop-in, under-mount, and vessel (similar to bowl setting on the countertop fed by a separate counter mounted faucet), The stub-out piping serving a lavatory is either 1 – 1/4” or 1 -1/2”. Most residential lavatories use a pop-up drain assembly. The overflow drain on a residential lavatory is an integral feature provided by the sink manufacturer.

- Lavatory ADA Requirements: Many lavatories are sold specifically for ADA compliance, but they are used more for commercial applications. ADA requirements require specific codes relating to the countertop height from the floor, the knee space under the sink, and the distances from the side and back walls.

- Lavatory Styles: Lavatory sinks are ordered based on shape, size, color, and mounting requirements, as well as the number of faucet holes and the distance between them.

- One-Piece: Cultured marble or other approved material, incorporates the countertop and sink being formed as one unit.

- Drop-in: A typical residential home utilizes a drop-in style lavatory that is either round or oval. A drop-in type lavatory sink requires a specific size hole cut into the countertop for the particular sink to be installed into the hole.

- Under Counter Mount: Considered an upgrade, under counter mounted sinks attach to the underside of finish grade holes based on templates of the sink in granite, composite, and other hard countertops. While some of these sinks are secured with retaining clip, many rely on modern adhesive caulks to adhere them to the countertop and support their full weight during use.

- Pedestal: A pedestal sink is a wall-hung sink with a decorative vertical leg known as a pedestal. The bowl is supported with brackets that are anchored to pieces of wood installed in the wall framing. The pedestal is not designed to be the sole support of the basin (bowl), but instead conceals the drain piping below the sink while providing a decorative styling.

- Lavatory Faucets: A lavatory faucet installs onto a plumbing fixture with various methods depending on the faucet type and manufacturer’s design. They can be installed in either fixture mount style sinks or deck mount (through the countertop) applications. The standard, and most common, lavatory sink has a 4” hole spread between the hot and cold handles. The term spread refers to the distance between the hot and cold faucet inlets. The two most common handle designs are a single-handle and a two-handle faucet. The middle hole of a three-hole lavatory sink is located in the center in the sink to receive the drainage operating assembly (pop-up) and/or a faucet spout connection.

- Lavatory Drains: The drain assembly for a lavatory faucet is known as a pop-up. The pop-up assembly consists of several different operating pieces that function as one unit. The pop-up rod is inserted through the faucet within the spout and connects to a linkage assembly below the sink that operates the pop-up plunger. All lavatory sink pop-up assemblies are 1 -1/4” tubular size. Most lavatories have an overflow port to eliminate water from rising over the rim of the fixture.

How To Install a Bathroom Vanity

Query \(\PageIndex{3}\)

Bathtub

Bathtubs are also known simply as tubs. A standard tub in a home is 5-0” in length and averages 30” wide. The depth of water a tub can hold varies with each specific tub design. Some tubs are sold separately, while others are sold with wall kits as a one-piece tub and shower unit or with various whirlpool features. A one-piece tub and shower unit is a fiberglass tub molded with the walls as a single unit. A tub is typically installed during the rough-in phase of a project. However, some drop-in style tubs, whirlpool tubs, and large-capacity garden tubs, are installed on top of tile or other solid surface are installed after the finished surface is complete.

The drain location is typically on one end of the tub that is known as the head wall. This is usually the same wall where the faucet is located and tubs are selected based on a left-hand or right-hand head wall design. The bottom surface of a tub slopes toward the drain. Every tub has an overflow hole (port) where a waste and overflow is installed.

- Bathtub Faucets: A tub faucet is intended to fill a tub. A tub faucet can either be deck-mounted or installed in a wall. Deck-mounted faucets are common for large-capacity tubs and whirlpool tubs. A faucet serving a tub or a shower is commonly referred to as a tub valve. Tub/shower valves can be used for tubs without a shower by installing a plug or cap in the shower riser port.

- Tub & Shower Faucets: A tub and shower combination faucet is capable of providing water for bathing or showering with the use of a diverter. Many different designs are available to divert the water flowing through a tub spout to flow through a showerhead. Diversion methods of a single-handle tub and shower faucet use either a diverter style tub spout or a push button diverter usually located directly below the faucet handle. A three-handle Tub and shower faucet design uses the middle handle as the diverter.

- Bathtub Drains: A bathtub drain assembly is called a bath waste and overflow (BW&O). A bathtub has an overflow port hole and a drain port that are always connected and installed as a pair (usually aligned with each other). Large capacity whirlpool tubs are more likely to have the holes in varying locations than a standard bathtub.

Installing a 1-Handle Posi-Temp Shower Valve: Copper to Copper

Query \(\PageIndex{4}\)

Installation – Sterling Ensemble Medley

Query \(\PageIndex{5}\)

Shower

Not part of a tub and shower combination.

- Shower ADA Requirements: ADA-compliant shower bases have a lower or no threshold and a larger square foot area than a typical non-handicap shower base. Many shower designs use a seat within the shower, and most handicap shower designs must have a seat. If a seat is constructed in a tiled shower on a wood floor, the plumber must provide waterproofing (ex: PVC liner) to the seat as well as the shower base. One-piece shower units that have a seat are typically premolded into the design of the shower.

- Shower Faucets: A shower faucet is intended to serve a shower head. Shower faucets and tub valves are interchangeable, however a combination tub/shower valve that does not incorporate an integrated diverter may be used with the tub port plugged or capped.

- Shower Drains: A shower base constructed on a wooden, and sometimes concrete, floor prepared to be covered with ceramic tile requires a safety pan. Most safety pans use a polyvinyl chloride (PVC) liner. A three-piece shower drain is required to ensure that water does not seep around the drain. The threaded top portion is adjustable to allow various tile thicknesses. The middle portion receives the top threaded portion and is bolted to the bottom portion. The bottom portion rests flush with the wood floor and connects the piping to the p-trap.

Oatey Shower Pan Liner Installation

Query \(\PageIndex{6}\)

Kitchen sink

The most common residential kitchen sinks have either a single bowl or a double bowl. Most kitchen sinks are surface mounted and are installed into a countertop during the trim-out phase of construction. Surface-mounted sinks are also known as self-rimming sinks and typically have holes for installing the faucet directly onto the sink. Solid surface countertops can utilize a sink mounted from under the countertop and incorporate deck mounted faucets. The common types of kitchen sinks used in residential construction are stainless steel and cast iron. The weight of a cast iron sink provides the necessary stability to maintain its permanent position on the countertop and does not require retainer clips when installed with an appropriate adhesive caulk. A plumber applies caulking to the edge of the cutout area of the countertop and places the cast iron sink into the hole. A stainless steel sink requires the sink to be fastened to the countertop using fastening clips provided. A kitchen sink can also serve a garbage disposal and dishwasher

- Kitchen Faucets: A kitchen faucet is usually installed before installing a kitchen sink. A kitchen faucet has a swivel spout that allows the water flow to be used in each bowl of a kitchen sink. The most common type of kitchen faucet requires a sink to have three faucet holes that are 4” apart or 8” from the hot and cold water supply connections to the faucet. Most kitchen sinks are offered as a three-hole design, but many popular faucet designs have a pull-out spout that is also the spray unit. If a separate handheld sprayer is used, a four-hole model sink must be selected. Most pull-out spout faucets are manufactured with an integral check valve. The center hole of a three-hole sink is normally aligned with the center of the sink.

- Kitchen Sink Drains: The drainage system serving a kitchen sink is connected to the fixture with a basket strainer. Regardless of the type or style of kitchen sink, the connection of the drainage system is the same, and all have 1 -1/2” drain connections. A rubber gasket is placed over the basket strainer from under the sink. A fiber (cardboard)-type gasket is placed between the tightening nut and rubber gasket.

Delta Faucets-How to Install a Single Handle Kitchen Faucet

Query \(\PageIndex{7}\)

Installing a Pfister 2-Handle Kitchen Faucet with a Sidespray – Harbor Collection

Query \(\PageIndex{8}\)

How-to Install a Stainless Steel Drop-In Sink | Moen Installation Video

Query \(\PageIndex{9}\)

How-to Install a Stainless Steel Undermount Kitchen Sink | Moen Installation

Query \(\PageIndex{10}\)

Laundry Sink

Also known as a laundry tray or utility sink. They are typically installed in the same room as a washing machine, or in a garage or workshop. Two most common types of laundry sink

designs are wall mounted, which requires a plumber to install wood backing in the

wall during the rough-in and a hanger bracket installed during trim-out; or with the four legs secured to the floor which requires a drill to install anchors into the floor.

- Laundry Sink Faucets: Laundry tub faucets usually have a 4” spread design and most laundry sink faucets have a swivel spout. Some laundry sink faucets have a hose thread on the outlet portion of a spout to allow a garden hose to be connected. For a hose-end spout to be legally installed, it must have a vacuum breaker to prevent backflow into the potable water supply.

- Laundry Sink Drains: The minimum size drain allowed by code to serve a laundry sink is 1 -1/2”. Most quality types of laundry sink basket strainers have a removable strainer. Because a laundry sink can receive discharge from a washing machine, a removable strainer should be installed.

How to Install the UTILATUB® Laundry/Utility Tub

Query \(\PageIndex{11}\)

Bidet

A bidet is a personal hygiene fixture that is usually matched in style and color with, and placed adjacent to, a toilet. A bidet’s faucet and drain assembly are sold based on the fixture design and typically sold as a pair with the toilet. The water supply must be protected against backflow with a vacuum breaker assembly. The water supply serving a bidet is typically a 3/8” supply tube similar to a lavatory. The base of a bidet, like a toilet, typically has two mounting holes to anchor the bidet to the floor.

- Bidet Faucets: A bidet faucet must be compatible with the fixture based on the faucet hole design for installing a particular faucet and a vacuum breaker if required. A vacuum breaker is required by code if the hygiene sprayer is located in the bowl area of a bidet because it is below the flood level rim of the bidet.

- Bidet Drains: A bidet’s drain assembly is very similar to a lavatory’s pop-up assembly. Most bidets that use vacuum breakers have a dedicated hole in the fixture while others are served with the backflow device installed in the piping system.