5.2: Conductors

- Page ID

- 3287

Conductors are required to create a circuit and carry the current that will operate different devices or loads. Conductors are normally made of copper with a plastic or fiber insulating coating covering them so that they do not contact anything. Exposed wires are not only a safety concern, they are a problem in the circuit if they contact each other.

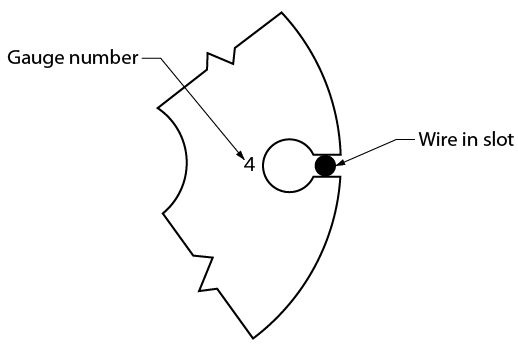

Conductors are rated according to the American Wire Gauge (AWG) system, which designates different gauges for wires of different thicknesses. Most conductors found in vehicles and equipment are braided multi-strand conductors because they can withstand vibration and motion better than solid conductors. Most wiring found in residential and industrial applications is solid conductors. Special measuring gauges (Figure \(\PageIndex{1}\)) are used to determine the actual physical wire size.

A conductor is normally shown on a wiring diagram by a straight line with a color notation and often a gauge or size notation.

A power cord is a flexible conductor used to supply electrical energy to electrical equipment. With plugs attached, these cords are used to attach appliances such as dryers and ranges to their receptacles. In industry, they are used to connect portable electrical equipment or machinery to receptacles. Conductors are covered with insulating material to prevent the unwanted flow of electric current. Various conditions of use dictate the type of insulating material:

- voltage rating

- temperature rating

- location (e.g., wet or dry or potential mechanical damage)