1.2: Dry Ingredients

- Page ID

- 21172

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)Wheat Flour

One of the most important ingredients in the baking process is flour. Almost every item made has some type of flour added. It is the main building block of breads, pastries and most cakes. The production of flour can be traced through the centuries to the beginning of civilization. An important fact for a baker to know is the difference between hard and soft wheat. This gives the baker the ability to know which type of flour to use for the application needed.

There are six different types of wheat grown in North America.

- Hard Red Winter - This versatile wheat can be used in a variety of baking applications as well as making Asian style noodles. The protein content of this milled wheat is between 10 to 15 %. This is a good choice for all purpose flour, hard rolls and flatbreads.

- Hard Red Spring - this wheat has a higher protein content 12 to 18 % and is primarily used to mix into flours. As a standalone flour, it the gluten formed is very strong and often difficult to form into bread. It is often added to improve bread flours and is used in making the high-end breads such as: artisan breads, pizza crust, croissants and rolls.

- Soft Red White - this flour has a weaker gluten formation due to a low protein content of only 8 to 11%. The weaker gluten makes this an excellent wheat for items such as cookies, crackers and pastries.

- Soft White - this a wheat has a low moisture content as well as low protein content 8 to 11 %. It also produces a whiter product, which makes it ideal for cakes, pastries, and some Middle Eastern flatbreads.

- Hard White - this is a newer type of wheat grown in the United States. It is used for making whiter wheat breads as well as Asian noodles, and flatbreads.

- Durum - this is the hardest of all wheats. It has the highest protein content 14 to 16 % as well as the high gluten content. It is primarily used in the production of pastas, couscous and Mediterranean breads.

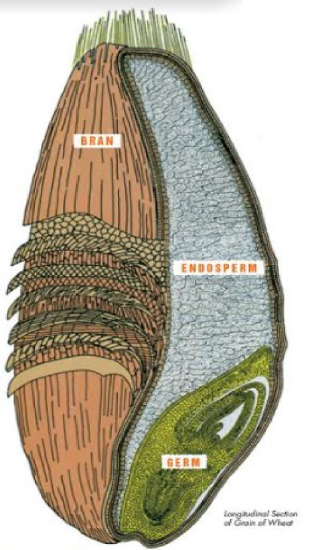

The Wheat Kernel

The wheat kernel is made up of three parts: bran, endosperm, and germ. During the milling process, the kernel is broken up and each part is milled and used.

- Bran - this is the hard outer casing of the kernel. It is darker in color than the inside. When looking at flour the brown specks present is the milled bran. It is removed from white flour. The bran is high in fiber, vitamins, minerals, proteins and fat.

- Germ - this is from where new wheat plants sprout. It has a very high fat content thus is will become rancid quickly. This leads to a very short shelf life of any flour that contains the germ.

- Endosperm - this is the inside part of the kernel. It makes up about 83% of the kernel. This is the part that white flour is derived. It is also the starchiest part of the kernel with about 68 to 76% starch. It contains protein and carbohydrates alone with vitamin B, iron, minerals and soluble fiber.

Image Wheat Foods Council

Milling Process

The purpose for milling to separate the parts of the wheat kernel into usable material. Thus, the endosperm has to be separated from the bran and germ. The endosperm is the part that becomes flour that we use in baking. All parts can be purchased for use in today’s market.

In the early years of milling, the wheat kernels were milled by smashing or rolling them between two large stones. This process gave a course grind to the stone but allowed the parts to be sifted and separated. This was a very laborious process. You can still find stone ground products today in some European markets but most flours in the US are no longer process this way. The most common stone ground products are stone ground grits and cornmeal.

Modern milling of wheat occurs by way of the break system.

Types of Flour used in Bakery

Bread Flour - this is a strong flour made from hard wheat. It offers a good amount of protein and thus offers a good gluten formation. You can purchase this bleached or unbleached. This type is usually reserved for commercial bakeries.

High-Gluten – We use this flour in class. It is a high protein flour that offers a good gluten formation also.

Cake Flour – this is weak flour made from soft wheat. It is normally pure white. It has a soft and silky feel to it. The gluten formation is low with this flour, which makes it an excellent flour for delicate pastries.

Pastry Flour - a weak flour that is also low in protein and thus low in gluten formation. It is stronger than cake flour however. The color is a creamy yellowish color.

All-purpose – this flour is a general use flour. It can be used in the place of each of the above flour. Its protein content is lower but has enough form a good gluten structure for bread making. Usually this is the home baker’s flour of choice.

Self-rising - this flour has the leavener added to it. Baking powder and salt. This is not used in the professional kitchen. Leavener tend to weaken over time so this can be an issue also when scaling recipes most have a leavener added and the amounts vary so not enough could ruin the product.

Meals

Corn meal – this is made from the endosperm of the corn kernel. It can be purchased in a variety of styles. It contains no gluten.

Nut meals - various nuts are ground into “flours” that can be used in baking. Almond and Hazelnut are the two most common. These also contain no gluten due to the absent of wheat in the product.

Sweeteners

Sugar - refined graduated sugar is a common item in the bake shop. It is used in almost every recipe as the main sweeter ingredient. It can also act as a tenderizer in products. This has no molasses left in it after refining.

Sugar is hydroscopic which means it absorbs moisture in the air and its surrounding.

Light brown sugar - this is sugar that has not been refined as much. It still has some molasses left in it. This gives it a slight addition of acidity. It will feel a bit wet when touched. When measuring this sugar you want to make sure you pack in into the measuring cup tight. If done correctly it will hold its shape when removed.

Dark Brown Sugar - this is sugar that has the highest amount of molasses left in it during the refining process. This has a slightly higher acid content than light brown sugar.

Molasses - a byproduct from the process of refining sugar. It is a thick darn brown liquid. It added moisture to baked goods helping then stay fresher longer.

Honey - a natural sugar syrup made by bees. The type of honey varies depending on the diet of the bees and the area in which they are kept. It is the only food that does not spoil. It may crystalize as it sits but it can be put into warm water, or heated to melt the crystals.

Invert Sugars - These are liquid sugars that are used in the baking kitchen. They can be added to recipes as sweeteners, or used to prevent crystallization of the granulated sugar. Corn syrup and glucose are two of the most common we use.

Fats

Butter - is made from the processing of heavy cream. As the cream is agitated, the fat molecules pull together and separates from the whey. It can be purchased in stores salted and unsalted. In the kitchen, unsalted butter is preferred so that salt can be measure into the recipes in the correct amounts. Butter will become solid when cold but soft at room temperature. It also has a very low melting point (90 to 95oF).

Margarine - This is a fabricated product from hydrogenated animal and vegetable fats. It also contains flavorings, emulsifiers and dyes to give it color. There are different types that can be purchase. It is cheaper than butter while still maintaining some flavor of butter.

Shortening

Regular – this is the shortening are referred to as plastic shortenings. They have a tough waxy texture with small fat particles. They have a good creaming ability and work well in flaky pie doughs because of their texture. Crisco is an example.

High-ratio - they spread easily through a batter. They are creations for use in recipes that have a high ratio of liquid and sugar to flour.

High-ration liquid - they have less hydrogenation which makes them pourable. This add moisture to cakes and batters. It also allows for easy air incorporation, which will give cakes a better rise and texture.

Dairy

Milk - this can be purchased in whole, 2 %, low fat, and skim. Each of these describes the amount of fat this is in the product. Milk today is sold as homogenized which means it has been through a process that keeps the fat and liquid from separating.

Heavy Cream - this has a higher percentage of fat in it. It can be used as is or whipped up and sweetened to make whipped cream. As with milk you can buy heavy cream with different fat percentages.

Butter Milk – this is used often in recipes but contains an acid that is countered by the addition of Baking soda.

Evaporated Milk - also known as “pet “milk. Evaporated milk is milk that has a percentage of the water removed. It is sold in cans unrefrigerated due to sterilization.

| Fat Amounts in Various Dairy Products | |

|---|---|

| Whole Milk | 8% |

| Skim Milk | < 1% |

| Heavy Cream | 30% to 40% |

| Half and Half | 10% to 18% |

Eggs

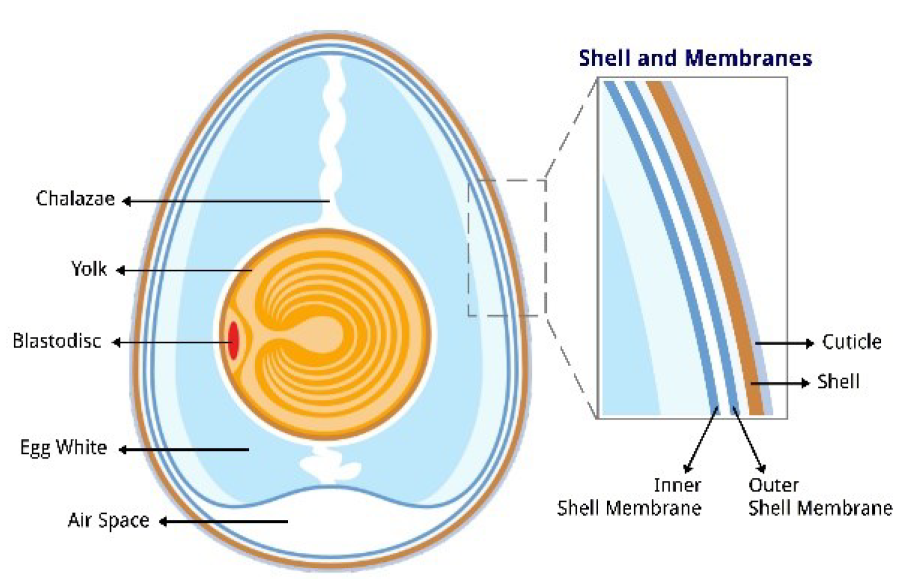

The egg is an essential ingredient used in the bake shop.

- The make of the egg is simple – yolk, white and shell. In the diagram you see how each in connected in the shell.

- The chalazae is the stringy white part you see when you crack the egg.

- The yolk is high in fat and protein. Lecithin is also found in the yolk and aid in thickening and emulsification of ingredients.

- The white is the lean part of the egg. It is used for meringues and coagulates when heated.

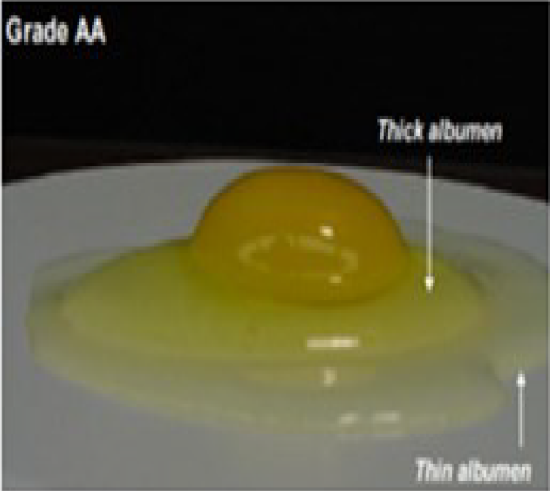

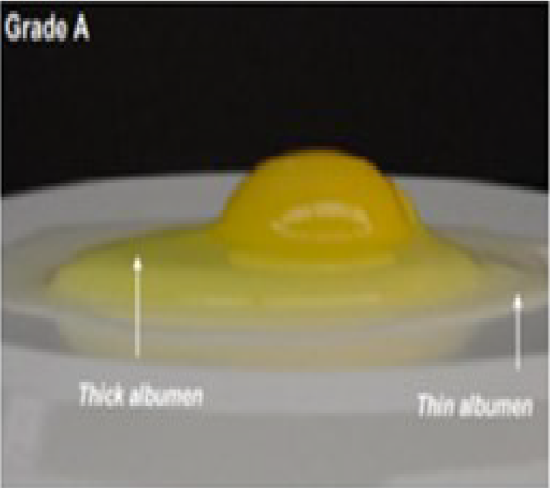

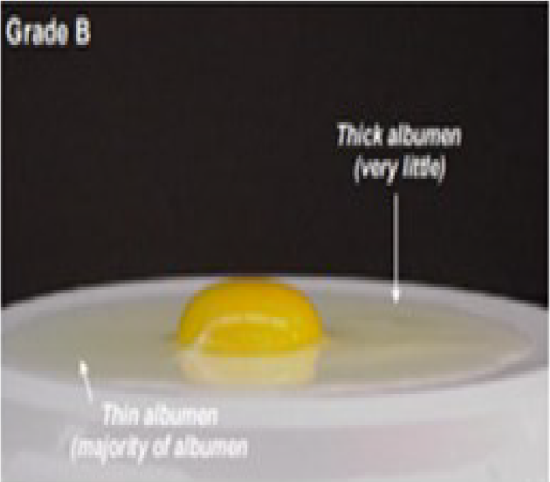

Grading and Weight of Eggs

The United States grading system for eggs is based on their quality but also size. There are 3 types of grades given to eggs AA, A and B.

| Approximate of Weights of a Large Egg | |

|---|---|

| One whole egg | 1.67 oz |

| One egg white | 1 oz. |

| One egg yolk | .67 oz. |

| 9 ½ whole eggs | 1 lb. |

| 16 egg whites | 1 lb. |

| 24 yolks | 1 lb. |

Yeast

The leavening agent in yeast doughs. It is a single cell fungi however there are many species and well as types. When fed the yeast will produce carbon dioxide and alcohol.

Types of Yeast

- Fresh or Cake - this is sold in bricks similar to butter. It is moist and perishable. If treated properly it will last about 2 week in the refrigerator. It can be froze to extend the life if not used right away.

- Active Dry - this must be rehydrated with warm water that is 4 times its weight. Yeast will die if the water temperature is 140oF or higher. Major issue with this yeast is that many of the yeast cells in the packet are dead and activing the rest can be problematic.

- Instant dry yeast - this yeast does not need to be dissolved in water to use it. It can be added to the dry ingredients and mixed due to its ability to absorb water quickly. This makes it the preferred yeast product of most bakers today.

Chemical Leaveners

These leaveners work by releasing gases caused by a chemical reaction.

Types of Chemical leaveners

- Baking Soda – sodium bicarbonate. The reaction for baking soda is done once liquid is added. Products that contain baking soda must be baked as soon as they are assembled. If allowed to sit the chemical reaction will take place and end causing the product to not rise once in the oven. They are generally used when acids are added to a recipe such as molasses, brown sugar, and some fruit juices and cocoa powder.

- Baking Powder – this is a combination of baking soda and an acid. This allows for the majority of the leavening to take place in the oven. Heat is need to leaving products that contain baking powder. The preferred type found in stores and bakeries is double acting baking powder.

Cocoa Powder

This is the powder that is left once the cocoa butter has been removed during the production of chocolate.

Types of Cocoa Powder

- Dutch-processed - the acid in this has been neutralized through a washing process. This gives the cocoa powder with a dark color, and smoother flavor.

- Cocoa powder – this is somewhat acidic and lighter in color.

Vanilla

This is the fruit of the orchid plant Vanilla. The fruit is cut, and cured which dries the pod allowing for the intense flavor due to minimal loss of the essential oils.

- Vanilla extract is made from soaking the cut vanilla beans in alcohol. It is allow to macerate until the desired flavor profile is reached. The beans are then removed and the product is bottle.

- Once you use a bean, it can be dried and used to make vanilla sugar. This is done by enclosing the bean and sugar in a container and allowing the sit. The vanilla flavor is permeate through the sugar.

- Dried Vanilla beans can also be ground and made into vanilla powder.