7.3: Facility Development

- Page ID

- 22097

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)The better the connection between customer and concept, the better the chances of success for the organization. With this in mind, remember that the location is the physical domain that allows the concept to come to life. Therefore, the building, concept, and customer elements must come together at the restaurant site. Some initial broad considerations begin this discussion.

- The type of customer the business will attract.

- The amount of construction or remodeling cost incurred to bring the facility online.

- Subsequently, the investment requirements from lending institutions or investors.

- The type of local ordinances and the state and federal laws that affect foodservice establishments

- The availability of workers in the trading area.

- The ease or difficulty in obtaining alcoholic beverage licenses.

- The parking availability for the operations customers as well as the ease of accessibility to your facility from roadways.

- Occupancy costs such as insurance, fire suppression, accessibility of restrooms, other handicap law requirements, and so forth.

- Zoning ordinances. One of the very first issues to investigate with regard to a location is the area zoning. Zoning ordinances for the location under consideration must allow your specific type of operation to do business at the location, and must permit adequate parking on or near the property.

To begin to think about what the physical facility should represent to a potential clientele. The operator must integrate the concept into the building design to position the concept as well as the delivery of products and services in the minds of those patrons the operation intends to attract. The successful foodservice operation combines the following elements of concept development into the actual design of the physical facility: market, menu, money, management, and method of execution. All will receive discussion in detail later in the chapter, but this initial grouping should help to center their importance to the restaurant's physical presence.

Market

You must properly examine the trading area to gather the appropriate demographic, psychographic, and behavioral profiles. An analysis of the data should render sufficient information to make segmentation choices and provide answers to the following relevant elements pertinent to the determination of what the physical facility should offer to the operation Before the facility can begin construction, the operation must have a clear idea about specifically 'who' the preferred clientele will be. Are they young, middle-aged, families, older couples? Each category of customer prefers certain amenities. Is the market large enough to generate sales and produce a profit? This question is reflective of the city, and trading area itself. It could equally to refer to different clientele brackets. If one intended segment of the market is not sufficient to cover the expenses of the operation and produce a profit, then additional segments must be included and the requirements of those additional patrons must receive consideration in the design process. Basic market elements would include:

Market Identification

What is the segmentation strategy? Based on the size of the city and trading area, choices are necessary to describe each segment of patrons the facility must attract.

Level of competition

What quality standard and level of functionality do direct competitors offer your intended patrons? What could you do to enhance the customer's experience and sense of obtained value?

Market Communication

How will we communicate with our target market? This question is important to consider when deciding on the facade, ground, lighting, signage, and logo design of the facility to name a few important items.

Customer wants or needs

This speaks directing to the sunk costs of the facility and subsequent menu pricing as an expenses incurred consequence. If customers feel a 'need' for the products and services of the restaurant, they will typically be willing to pay a bit more than customers who are will to more toward substitutes to obtain greater value should financial considerations come into play. Will a quality assurance plan be developed that will encourage the customer to return because of superior service and, or, product quality? The operation and facility must always deliver what the concept marketing indicates patrons can expect. Too often operations fall short of advertised promises. The design the facility to meet both the desired and publically conveyed standards. The operation must maintain the public trust and its perception of value. Will internal marketing successfully sell the customer additional services or products and maintain different avenues of product and service delivery?

From the broad perspective, the design the facility to display products and logo items of the concept. Additionally “How will delivery orders be handled if that form of service is offered? Will customers placing take-out orders have to dress up and mingle with seated patrons? Will the facility have a convenient walk-up design for those wishing to remain casually dressed? How will payment be made and food delivered to these customers. The devil is always in the design. However, the proper design is profitable.

Most operations fail to plan the various ways to reach customers with their concept. All areas of the operation should complement each other without impeding any other area. Each customer should receive a superior product and service experience no matter what manner of delivery customers ’prefer. Stated differently, many operators fail to consider delivery or take-out as an expansion of the dining room and a decision to utilize the operation when the customer makes the decision to use the operation's services in a capacity other than 'seated' dining - as such, this is business that would be lost if avenues other than sit-down dining were not offered. Understanding how customers wish to utilize your products and service is vital to your success. A classic mistake made by both large corporations and individual restaurant operators is to conduct the market analysis and then fail to act on the information obtained.

Menu

The menu has a tremendous influence on the design and success of a food operation. An operator must constantly frame his or her thinking of the menu as the primary or sole source of revenue for the operation that will also cover the expenditures of the operation on a monthly or yearly basis, and provide the profits sought by the organization. Will the menu be static, seasonal, broad, or narrow? Is there a balance among sautéed, gridded, and fried items - or will one station bear the burden of production? From a design and layout perspective, these are just some of the factors determined by the menu:

Space required

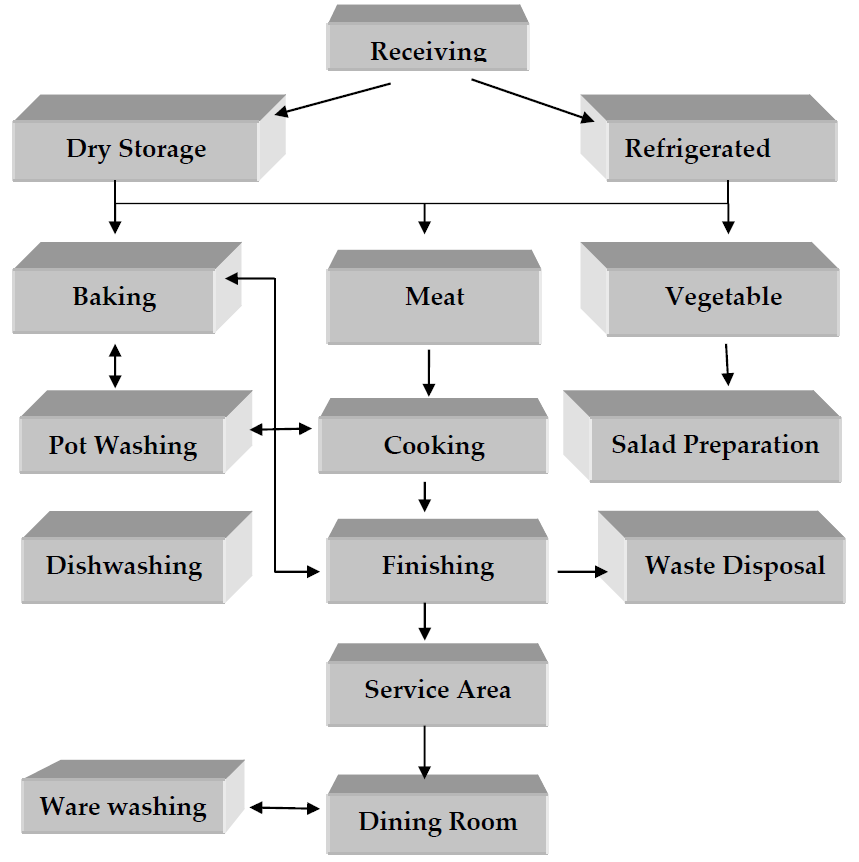

A complex menu requires more space to prepare items than a limited, or simple, menu because separate workstations and additional equipment are necessary. Depending on the amount of space available in a prime location, 'make' or 'purchase' decisions may well become practical considerations. Will we prepare artisan breads, rolls, or desserts in house? Is it more prudent to outsource these items? Do we actually need an on premise bakery? Will we have to plate-up desserts with ice cream in the hot kitchen? How will we segregate and partition the kitchen? How will we stock preparation areas? Product control considerations? The list can be extensive. The HACCP orientation required product to flow from the back of the restaurant to the front to minimize cross contamination. A normal restaurant kitchen flow follows. Notice that dishwashing and ware washing can occur at different locations within the facility. This type of configuration separates dirty pots and pans found in the kitchen from glassware, plates, and utensils in use in the dining area. Waste disposal is another area that can be located more conveniently to the outside trash bin.

Typical Kitchen Product/Traffic Flow

Equipping the Facility

Major Categories of Kitchen Equipment

- Receiving and storage of food

- Fabrication of food

- Assemble, hold, and serve

- Clean-up and sanitize the kitchen and kitchen ware

Storage

- Dry storage

- Cold storage

- Freezer Storage

Space Analysis

- Dock, receiving area

- office, locker room, toilets

- storage area, dry, cold, freezer, cleaning supplies, dishes, and utensils

- preparation area

- ware-washing

- production are

- bakery

- dining room

- service areas

- wait stations

Pre-prep - Fabrication - Preparation

The key thought about this area is that it is where raw (or processed) foods begin their journey to their final destination, the plate of the guest. This area is for breaking down different cuts of beef, seafood preparation, chicken, opening and prepping crates of fresh produce, and storing or not storing these items.

Preparation items needed

- worktables

- compartment sinks

- refrigerators

- freezers

- food and condiment wells

- cutting boards

- portion scales

- meat saws

- grinders

- mobile carts

- speed racks

- shelving

- knife and tool compartments

Garde Manger items

- Hand Held and small appliances

- Salad spinner

- Graters

- Portable mixers

- Blenders’

- Knives

- Scrub brushes

- Kitchen towels

- Color-coded bowls, cutting boards

- Cross-contamination controls

Production area

Dry Heat: sauté, broil, roast, fry, and bake

Moist heat: braise, boil, and steam

Dry and moist heat cooking equipment, refrigerated storage, tool storage, exhaust system, fire suppression system, refrigerated prep lines, steam holding tables, compartment sink, hand-washing sink(s). The following placement suggestions help to segregate equipment based on task and function. These groupings also increase the ease and maneuverability of the kitchen staff. For example, you do not want the grill person walking around a steam kettle or a tilt skillet to perform a sauté function during a slower period.

- Volume cooking to the back, to order cooking to the front.

- Group large-volume cooking together (deck ovens, steam-jacketed kettles, and tilt skillets).

- In a la carte kitchens, group together fryers, broilers, open-burner ranges, and steam equipment.

General equipment requirements

The following are the major types of equipment found in restaurant kitchens: broilers, grills, stoves, ovens, frying equipment, steamers, prep lines, holding equipment, convection ovens, tilt-skillet for breakfast items, sauté, braise, roast, steamer, poacher, or a hot-hold unit.

Bakery

On-site baking requires additional room and equipment. What baked goods will be prepared on site, and which, if any, will be purchased? Will baking occur from scratch? Will you use premixed or frozen items? Choice determines equipment needs. Depending on the type of baking done, the location of the bakery can be a crucial choice. Considerations include cold dessert preparation and holding, preparation area for from scratch bread or roll products, and access to dishwashing. While this production area requires some thought, products produced can achieve signature status for the restaurant.

Assembly, Holding, and Serving

- Beverage equipment

- Cold/ hot -serving equipment

- Infrared warmers

- Coffee brewers

- Condiment holding

- Mobile equipment

- Plates and saucers (hot or cold),

- Glasses, and so forth

Cleaning and Sanitation

- Cleaning and sanitizing supplies

- Cleaning sink(s)

- Three - compartment sink(s)

- Glassware storage

- Water heating equipment

- Dishwashing equipment

- Ware washing equipment

- Hand sink(s)

Service area size and design

The greater the number of menu items, the more area required for service in the kitchen as well as staging and work stations necessary in the dining room (each different entrée requires a point of service and each form of beverage a dispenser). Stated a bit differently, how far do you expect your service staff to travel to obtain or prepare necessary amenities for the customer? How involved in the preparation of certain products would you expect the service staff to be engaged in? Table setting, bread, butter, drink and/or dessert service? These questions speaks to the spatial aspects of floor plans as well as the number of tables that a server can adequately handle in terms of movement and product/service delivery.

General Considerations

Dishwashing

Complex menus require multiple plates, dishes, and utensils, so the dishwashing area and machine capacity will need to be greater than in the case of simple menus. Based on the size of the operation, will one dishwashing area suffice to maintain a smooth and efficient service operation? Should we construct one dish area for the kitchen and one for the dining room items such as plates, glasses, and utensils? A well-planned ware-washing arrangement could reduce the amount of plates, glasses and flatware necessary to the flow of service.

Types of cooking equipment

Complex menus require multiple types of equipment, especially in the final preparation area, where it may be necessary to steam, fry, bake, and sauté. Which pieces of equipment are necessary to execute the menu? Which items utilize the same pieces of equipment? What about preparation for different day parts? Is the intended equipment sufficient to prep and prepare items for dinner while luck is in progress? Can we receive multiple food deliveries per week that would reduce the need for a freezer? Product procurement is an often-overlooked consideration to space allotment in the kitchen.

Equipment capacity

Limited menus may require relatively few pieces of equipment but with large capacities. Complex menus may require many different types of equipment with relatively smaller capacities.

Size of dry and refrigerated storage areas

The size of the dry and refrigerated storage areas directly relates to the ingredients needed to execute the menu. What are the packaging dimensions for these necessary ingredients - both dry and those needing refrigeration or freezing? These issues deserve careful consideration during design to accomplish a storage area and scheme that facilitated product safety, security, freshness, taking inventory, and product rotation.

While product specifications are easily obtainable from the market suppliers, one important aspect of procurement often goes over looked when space decisions are considered. How often will the operation receive deliveries from suppliers? The projected volume of the restaurant should be a design factor along with the frequency of delivery when determining spacing needs. “Just in time” ordering requires less space. For instance, products from a supplier that delivers three times a week as opposed to once a week would require less space for the products they provide to the operation. The operator, for example, does not have to project customer volume with the addition of a pad should that volume increase. The products utilized for a “larger than expected” Monday dinner crowd could be easily replenished on Wednesday rather than having to take a chance on running out of ingredients before the following week's shipment.

Number of employees

Kitchen space must also consider the number of people working in the kitchen area. Factors that to consider would include the size and type of menu, the diversity of the menu, and the volume of the restaurant. Other considerations in terms of equipment is the necessity to turn tables requiring more ‘fire power’ in the kitchen, and placement of equipment to allow ease of operation by fewer staff members during slower periods – allowing kitchen staff to easily oversee more than production area during slower periods in the day.

The financial investment required

Again, this is a function of what you need to kitchen to produce. If your design requires a ‘show kitchen’ then the quality of the equipment will be visible to the guests and should be appropriate for viewing and the equipment arrangement should reflect that purpose. In such kitchens, cleanliness is paramount and thus an important consideration. This would equally extend to the type of menu offerings that will allow functionality and appearance.

A kitchen design ‘closed’ from customer view allows the operator to utilize second hand equipment to reduce startup costs. This is an important consideration if money is limited. As the restaurant becomes established, the income produced from sales revenue can be useful to purchase new equipment to replace the older equipment. Modern equipment requires less maintenance and comes with a warranty while second hand equipment comes ‘as is’ and the purchaser assumes all risk for repairs or replacement. It is important to note that many pieces of equipment have long life expectancies and should receive strong consideration in a new foodservice operation.

When considering the equipment purchases, the life span of the equipment you will need to operate the restaurant become important. Determining what equipment should be new and what second-hand equipment could help you to reduce your initial expenditure is a major financial consideration. Every dollar you can allocate toward marketing and promoting the operation is key to your success. The following table indicates the useful life span of many of the pieces of equipment your restaurant might utilize.

An additional benefit of second hand equipment will come in the approval of lender. A second hand equipment purchase is normally at ‘market value’ – the actual worth of the equipment. Thus, the purchase price closely resembles the amount the equipment would bring if put up for sales later. Further, you collateralizing market value cost with your lender as opposed to the inflated cost of new equipment what will depreciate in value – but not your monthly payments those pieces of equipment. Always consider the ‘durability’ and ‘technical’ aspects regarding maintenance of equipment when making this type of decision.

Restaurant Equipment Useful Lifespan

| Item | Expected Life (Years) |

|---|---|

| Convection ovens | 8 to 10 |

| Deck ovens | 10 to 15 |

| Rotary ovens | 12 to 20 |

| Mixers | 15 to 25 |

| Ranges | 10 to 15 |

| Steam-jacked kettles | 15 to 25 |

| Food Choppers | 10 to 15 |

| Vertical cutter-mixers | 12 to 15 |

| Tilt skillets | 12 to 20 |

| Grills | 8 to 12 |

| Fryers | 8 to 12 |

| Broilers | 8 to 12 |

| Steamers - high and medium pressure | 10 to 15 |

| Steamers - convection | 8 to 12 |

| Walk-in refrigerators/freezers | 12 to 20 |

| Reach-in refrigerators/freezers | 8 to 12 |

| Coffee urns | 8 to 12 |

| Ware-Washing machines | 10 to 15 |

| Shelving - stainless steel | 25 to 40 |

| Shelving - glavanized wire | 25 to 40 |

| Ice machines | 8 to 12 |

| Hoods/ventilation systems | 5 to 8 |

Successful capitalization of a food facility includes funds to cover the following elements of the facility:

- Planning costs

- Building construction or renovation

- Equipment (fixed)

- China, glassware, utensils

- Furniture and fixtures

- Décor

- Start-up and operating costs

- Two stages – the preliminary identification of financial support, and after concept development securing investors or lenders.

Preliminary Planning

Development – refers to the size and complexity of a foodservice facility design project. You can divide ‘development’ into four levels of complexity, each of which requires the involvement of different individual and different amounts of planning time.

- The development stage influences the design approach taken by the owner or manager depending on complexity.

- It is an important ‘first step’ before planning begins.

Stage 1 - Simple Development

Involves no more than the selection of a major piece of equipment or the replacement of a small area of a foodservice facility. Typically, the completion of this stage comes to completion out under the direction of the owner, or a manager, with the help of an equipment dealer. Examples of stage one include:

- Replacement of a dish machine

- Installing or replacing a display refrigerator

- Designing or changing a service counter

- The purchase and installation of an outdoor walk-in freezer, etc.

Stage 2 - Significant Development

Involves the renovation of a significant portion of an existing foodservice facility. A full complement of professionals is necessary at stage 2 because such projects are complex and require expertise in construction, engineering, and foodservice equipment layout and design.

Professionals involved from Stage 2 development onward:

- An owner

- An architect

- Mechanical and electrical engineers

- Foodservice facility design consultant

- Construction company or general contractor

- Kitchen equipment contractor.

Stage 3 - Complete Development

Projects involve the complete renovation of an existing foodservice facility or the design and construction of a new foodservice facility.

- Renovating the dietary department of a hospital

- Construction of a new theme restaurant

- Renovation of the kitchen, service, and dining areas in a country club

- Development of foodservice for a new hotel

The planning process for renovation of a foodservice facility often is even more complex than designing a new facility because of the:

- Difficulty of dealing with existing walls, structural members, utilities, and space and the demolition of parts of the existing structure.

- Decisions must consider which pieces of existing equipment should or could be useful in the newly renovated facility.

- Time element that can take from one to three years from design to completion.

Stage 4 - Large Scale Development

Projects that involve the development of a chain or franchise prototype.

- Constructed in multiple locations

- Inefficiencies in design or inadequacies in equipment can occur hundreds of times and thus will be exceptionally expensive to correct.

- Involves the full complement design team and the following: a corporate strategy; a well-researched marketing plan; complex financial planning; strong management team.

The food facility design at stage 4 must fit the needs of the:

- Menu

- Market

- Strategy

- Financial package developed by the corporation.

Professionals involved:

- Design team

- Investors / owners of the corporation

- Marketing consultants

- Financial planners

- Bankers

- Corporate staff specialists

Once the scope has been determined and the budget approved, the project can move forward to the next step in the process.