4.2: Inspection and Grading of Meat and Poultry - What Are the Differences?

- Page ID

- 21243

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\( \newcommand{\id}{\mathrm{id}}\) \( \newcommand{\Span}{\mathrm{span}}\)

( \newcommand{\kernel}{\mathrm{null}\,}\) \( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\) \( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\) \( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\id}{\mathrm{id}}\)

\( \newcommand{\Span}{\mathrm{span}}\)

\( \newcommand{\kernel}{\mathrm{null}\,}\)

\( \newcommand{\range}{\mathrm{range}\,}\)

\( \newcommand{\RealPart}{\mathrm{Re}}\)

\( \newcommand{\ImaginaryPart}{\mathrm{Im}}\)

\( \newcommand{\Argument}{\mathrm{Arg}}\)

\( \newcommand{\norm}[1]{\| #1 \|}\)

\( \newcommand{\inner}[2]{\langle #1, #2 \rangle}\)

\( \newcommand{\Span}{\mathrm{span}}\) \( \newcommand{\AA}{\unicode[.8,0]{x212B}}\)

\( \newcommand{\vectorA}[1]{\vec{#1}} % arrow\)

\( \newcommand{\vectorAt}[1]{\vec{\text{#1}}} % arrow\)

\( \newcommand{\vectorB}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vectorC}[1]{\textbf{#1}} \)

\( \newcommand{\vectorD}[1]{\overrightarrow{#1}} \)

\( \newcommand{\vectorDt}[1]{\overrightarrow{\text{#1}}} \)

\( \newcommand{\vectE}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash{\mathbf {#1}}}} \)

\( \newcommand{\vecs}[1]{\overset { \scriptstyle \rightharpoonup} {\mathbf{#1}} } \)

\( \newcommand{\vecd}[1]{\overset{-\!-\!\rightharpoonup}{\vphantom{a}\smash {#1}}} \)

\(\newcommand{\avec}{\mathbf a}\) \(\newcommand{\bvec}{\mathbf b}\) \(\newcommand{\cvec}{\mathbf c}\) \(\newcommand{\dvec}{\mathbf d}\) \(\newcommand{\dtil}{\widetilde{\mathbf d}}\) \(\newcommand{\evec}{\mathbf e}\) \(\newcommand{\fvec}{\mathbf f}\) \(\newcommand{\nvec}{\mathbf n}\) \(\newcommand{\pvec}{\mathbf p}\) \(\newcommand{\qvec}{\mathbf q}\) \(\newcommand{\svec}{\mathbf s}\) \(\newcommand{\tvec}{\mathbf t}\) \(\newcommand{\uvec}{\mathbf u}\) \(\newcommand{\vvec}{\mathbf v}\) \(\newcommand{\wvec}{\mathbf w}\) \(\newcommand{\xvec}{\mathbf x}\) \(\newcommand{\yvec}{\mathbf y}\) \(\newcommand{\zvec}{\mathbf z}\) \(\newcommand{\rvec}{\mathbf r}\) \(\newcommand{\mvec}{\mathbf m}\) \(\newcommand{\zerovec}{\mathbf 0}\) \(\newcommand{\onevec}{\mathbf 1}\) \(\newcommand{\real}{\mathbb R}\) \(\newcommand{\twovec}[2]{\left[\begin{array}{r}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\ctwovec}[2]{\left[\begin{array}{c}#1 \\ #2 \end{array}\right]}\) \(\newcommand{\threevec}[3]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\cthreevec}[3]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \end{array}\right]}\) \(\newcommand{\fourvec}[4]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\cfourvec}[4]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \end{array}\right]}\) \(\newcommand{\fivevec}[5]{\left[\begin{array}{r}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\cfivevec}[5]{\left[\begin{array}{c}#1 \\ #2 \\ #3 \\ #4 \\ #5 \\ \end{array}\right]}\) \(\newcommand{\mattwo}[4]{\left[\begin{array}{rr}#1 \amp #2 \\ #3 \amp #4 \\ \end{array}\right]}\) \(\newcommand{\laspan}[1]{\text{Span}\{#1\}}\) \(\newcommand{\bcal}{\cal B}\) \(\newcommand{\ccal}{\cal C}\) \(\newcommand{\scal}{\cal S}\) \(\newcommand{\wcal}{\cal W}\) \(\newcommand{\ecal}{\cal E}\) \(\newcommand{\coords}[2]{\left\{#1\right\}_{#2}}\) \(\newcommand{\gray}[1]{\color{gray}{#1}}\) \(\newcommand{\lgray}[1]{\color{lightgray}{#1}}\) \(\newcommand{\rank}{\operatorname{rank}}\) \(\newcommand{\row}{\text{Row}}\) \(\newcommand{\col}{\text{Col}}\) \(\renewcommand{\row}{\text{Row}}\) \(\newcommand{\nul}{\text{Nul}}\) \(\newcommand{\var}{\text{Var}}\) \(\newcommand{\corr}{\text{corr}}\) \(\newcommand{\len}[1]{\left|#1\right|}\) \(\newcommand{\bbar}{\overline{\bvec}}\) \(\newcommand{\bhat}{\widehat{\bvec}}\) \(\newcommand{\bperp}{\bvec^\perp}\) \(\newcommand{\xhat}{\widehat{\xvec}}\) \(\newcommand{\vhat}{\widehat{\vvec}}\) \(\newcommand{\uhat}{\widehat{\uvec}}\) \(\newcommand{\what}{\widehat{\wvec}}\) \(\newcommand{\Sighat}{\widehat{\Sigma}}\) \(\newcommand{\lt}{<}\) \(\newcommand{\gt}{>}\) \(\newcommand{\amp}{&}\) \(\definecolor{fillinmathshade}{gray}{0.9}\)The inspection and grading of meat and poultry are two separate programs within the U.S.Department of Agriculture (USDA). Inspection for wholesomeness is mandatory and is paid for with public funds. Grading for quality is voluntary, and the service is requested and paid for by meat and poultry producers/processors.

- Mandatory Federal Inspection

- Voluntary Federal inspection

- Grading

- USDA Grades for Meat and Poultry

- Beef

- Quality Grades

- Yield grades

- Veal/Calf

- Lamb

- Pork

- Poultry

- Food Safe Families

Mandatory Federal Inspection

American consumers can be confident that the Food Safety and Inspection Service (FSIS), the public health agency in the USDA, ensures that meat and poultry products are safe, wholesome, and correctly labeled and packaged.

Under the Federal Meat Inspection Act and the Poultry Products Inspection Act , FSIS inspects all raw meat and poultry sold in interstate and foreign commerce, including imported products. The Agency monitors meat and poultry products after they leave federally inspected plants.

In addition, FSIS monitors State inspection programs , which inspect meat and poultry products sold only within the State in which they were produced. The 1967 Wholesome Meat Act and the 1968 Wholesome Poultry Products Act require State inspection programs to be "at least equal to" the Federal inspection program. In states that choose to end their inspection program or cannot maintain this standard, FSIS must assume responsibility for inspection within that State.

FSIS does allow under a final rule State-inspected establishments with 25 or fewer employees to ship meat and poultry products in interstate commerce because of a new voluntary cooperative agreement program. Meat and poultry products produced under the program that have been inspected and passed by designated State personnel will bear an official Federal mark of inspection and will be permitted to be distributed in interstate commerce. FSIS will provide oversight and enforcement of the program.

In these efforts to protect the safety and integrity of meat and poultry products, FSIS works with many other agencies, including other agencies within the USDA, State inspection programs, the Food and Drug Administration of the U.S. Department of Health and Human Services, and the Environmental Protection Agency.

Since the Federal inspection program began at the turn of the twentieth century, the meat and poultry industries have grown and changed significantly. In the early 1900's, most meat came from local slaughter plants and was used locally. Further processing was limited to simple products such as sausages. Today, however, a wide variety of meat and poultry products are on the market. Animals are slaughtered and meat is processed in sophisticated, high-volume plants. The meat is often shipped great distances to reach consumers.

As the industry changed, FSIS began changing inspection. In earlier days, the primary concern of the inspectors was animal diseases, and they relied almost exclusively on visual inspection of animals, products, and plant operations. However, refinements in animal production reduced disease and created a more homogeneous animal population. Thus, the concerns of today's inspectors are broader and include unseen hazards such as microbiological and chemical contamination.

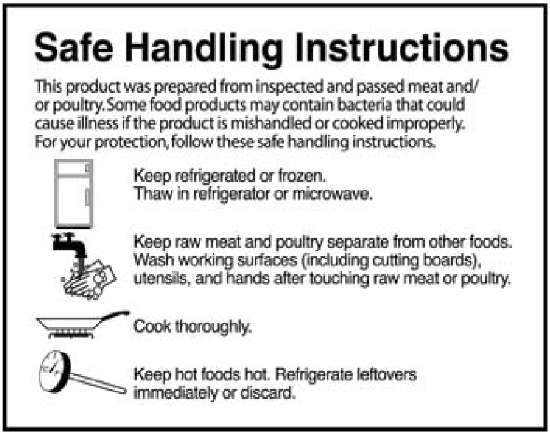

The requirements in the "Pathogen Reduction; Hazard Analysis and Critical Control Point (HACCP) Systems" final rule are designed to minimize the likelihood of harmful bacteria contaminating raw meat and poultry products. However, some bacteria could be present and might become a problem if meat and poultry are not handled safely. To assist food handlers, the USDA requires that safe handling instructions be put on all packages of raw and not fully cooked meat and poultry.

FSIS's HACCP Systems mandate measures to target and reduce the presence of pathogenic organisms in meat and poultry products. These measures include FSIS testing to verify pathogen reduction performance standards are being met; plant microbial testing to verify process control for fecal contamination; written sanitation standard operating procedures (SOPs); and a mandatory HACCP system in all meat and poultry plants. The implementation of HACCP by FSIS helps ensure the safety of the meat, poultry, and egg products supply. To learn more, visit FSIS's Web page on HACCP.

Every establishment is required to reassess the adequacy of its HACCP plan at least annually and whenever any changes occur that could affect its hazard analysis or alter its HACCP plan. The establishment may reassess its HACCP plan, or plans, any time during the calendar year to meet the annual reassessment requirement.

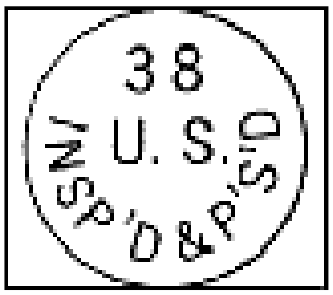

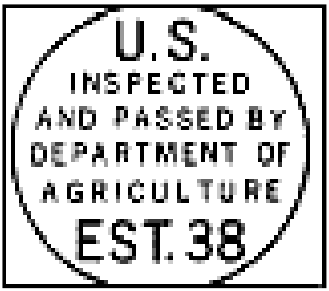

Meat that has been federally inspected and passed for wholesomeness is stamped with a round purple mark. The dye used to stamp the grade and inspection marks onto a meat carcass is made from a food-grade vegetable dye and is not harmful. (The exact formula is proprietary/owned by the maker of the dye.) The mark is put on carcasses and major cuts. After trimming, the mark might not appear on retail cuts such as roasts and steaks. However, meat that is packaged in an inspected facility will have an inspection mark which identifies the plant on the label.

Inspection mark on raw meat

Inspection mark on raw meat

Inspection mark on raw poultry

Inspection mark on raw poultry

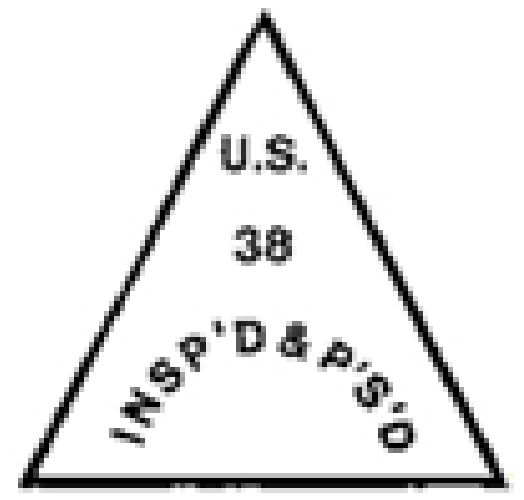

Inspection mark on processed products

Inspection mark on processed products

Voluntary Federal inspection for animals not covered under mandatory inspection (i.e., buffalo, rabbit, reindeer, elk, deer, and antelope) is handled under the Agricultural Marketing Act. This Act gives the Secretary of Agriculture the authority to take whatever steps are necessary to make the product marketable. The FSIS inspector must have knowledge about that particular species and the carcass must fit available equipment in the plant. Businesses that request voluntary inspection must pay an hourly fee for the service whereas mandatory inspection is funded by tax dollars.

For voluntary inspection, the mark of inspection (as referenced in 9 CFR 352.7-Marking Inspected Products) illustrates the mark to be the shape of a triangle for exotic species.

For application to exotic animal carcasses, primal parts and cuts therefrom, exotic animal livers, exotic animal tongues, and exotic animal hearts.

The establishment number of the official exotic animal establishment where the product is prepared shall be used in lieu thereof.

For the inspection of rabbits, as per 9 CFR 354.63 the mark of inspection is the same as the inspection mark for raw poultry.

Grading

After meat and poultry are inspected for wholesomeness, producers and processors may request that they have products graded for quality by a licensed Federal grader. The USDA's Agricultural Marketing Service (http://www.ams.usda.gov) is the agency responsible for grading meat and poultry. Those who request grading must pay for the service. Grading for quality means the evaluation of traits related to tenderness, juiciness, and flavor of meat; and, for poultry, a normal shape that is fully fleshed and meaty and free of defects.

USDA grades are based on nationally uniform Federal standards of quality. No matter where or when a consumer purchases graded meat or poultry, it must have met the same grade criteria. The grade is stamped on the carcass or side of beef and is usually not visible on retail cuts. However, retail packages of beef, as well as poultry, will show the U.S. grade mark if they have been officially graded.

The grade symbol and wording are no longer copyrighted; however, according to the Truth in Labeling Law, it is illegal to mislead or misrepresent the shield or wording.

USDA Grades for Meat and Poultry

Beef

Beef is graded as whole carcasses in two ways:

- quality grades - for tenderness, juiciness, and flavor; and

- yield grades - for the amount of usable lean meat on the carcass. There are eight quality grades for beef. Quality grades are based on the amount of marbling (flecks of fat within the lean), color, and maturity.

Quality Grades:

- Prime grade is produced from young, well-fed beef cattle. It has abundant marbling and is generally sold in restaurants and hotels. Prime roasts and steaks are also excellent for dry-heat cooking due to the age of the animal, and less connective tissue (broiling, roasting, or grilling).

- Choice grade is high quality, but has less marbling than Prime. Choice roasts and steaks from the loin and rib will be very tender, juicy, and flavorful and are, like Prime, suited to dry-heat cooking. Many of the less tender cuts, such as those from the rump, round, and blade chuck, can also be cooked with dry heat if not overcooked. Such cuts will be most tender if "braised" — roasted, or simmered with a small amount of liquid in a tightly covered pan.

- Select grade is very uniform in quality and normally leaner than the higher grades. It is fairly tender, but, because it has less marbling, it may lack some of the juiciness and flavor of the higher grades. Only the tender cuts (loin, rib, sirloin) should be cooked with dry heat. Other cuts should be marinated before cooking or braised to obtain maximum tenderness and flavor.

- Standard and Commercial grades are frequently sold as ungraded or as "store brand" meat.

- Utility, Cutter, and Canner grades are seldom, if ever, sold at retail but are used instead to make ground beef and processed products.

Note: Grades such as Prime, Choice and Select are not acceptable terms for raw cuts of pork or poultry

Yield grades range from "1" to "5" and indicate the amount of usable meat from a carcass. Yield grade 1 is the highest grade and denotes the greatest ratio of lean to fat; yield grade 5 is the lowest yield ratio. Though yield grades are not something consumers normally see, they are most useful when purchasing a side or carcass of beef for the freezer.

Veal/Calf

There are five grades for Veal/Calf: prime, choice, good, standard, and utility.

Prime and choice grades are juicier and more flavorful than the lower grades. Because of the young age of the animals, the meat will be a light grayish-pink to light pink, fairly firm, and velvety. The bones are small, soft, and quite red. Cuts such as chops can be cooked by the dry- heat methods of roasting, grilling or broiling.

Lamb

There are five grades for lamb. Normally only two grades are found at the retail level — prime and choice. Lower grades of lamb and mutton (meat from older sheep) — good, utility, and cull — are seldom marked with the grade. Lamb is produced from animals less than a year old. Since the quality of lamb varies according to the age of the animal, it is advisable to buy lamb that has been USDA graded.

- Prime grade is very high in tenderness, juiciness, and flavor. Its marbling enhances both flavor and juiciness.

- Choice grade has slightly less marbling than prime, but still is of very high quality. Most cuts of prime and choice grade lamb (chops, roasts, shoulder cuts, and leg) are tender and can be cooked by the dry-heat methods (broiling, roasting, or grilling). The less tender cuts — breast, riblets, neck, and shank — can be braised to make them tenderer.

Pork

Pork is not graded by USDA quality grades as it is generally produced from young animals that have been bred and fed to produce more uniformly tender meat. Appearance is an important guide in buying fresh pork. Look for cuts with a relatively small amount of fat over the outside and with meat that is firm and grayish pink in color. For best flavor and tenderness, meat should have a small amount of marbling.

Pork's consistency makes it suitable for a variety of cooking styles. Chops can be prepared by pan broiling, grilling, baking, braising, or sautéing. Ribs can be braised, roasted, or grilled. Slow cooking yields the most tender and flavorful results. Tenderloins are considered to be the most tender and tasty cut of pork.

Poultry

The USDA grades for poultry are A, B, and C.

- Grade A is the highest quality and the only grade that is likely to be seen at the retail level. This grade indicates that the poultry products are virtually free from defects such as bruises, discolorations, and feathers. Bone-in products have no broken bones. For whole birds and parts with the skin on, there are no tears in the skin or exposed flesh that could dry out during cooking, and a good covering of fat under the skin. Also, whole birds and parts will be fully fleshed and meaty. The U.S. grade shield for poultry may be found on the following chilled or frozen ready- to-cook poultry products: whole carcasses and parts, as well as roasts, tenderloins, and other boneless and/or skinless poultry products that are being marketed. There are no grade standards for necks, wing tips, tails, giblets, or ground poultry.

- Grades B and C poultry are usually used in further-processed products where the

poultry meat is cut up, chopped, or ground. If sold at retail, they are usually not grade

identified.

Food Safe Families

By following four simple steps, you can help keep your family safe from food poisoning at home.

- CLEAN: Wash hands and surfaces often.

- SEPARATE: Separate raw meats from other foods.

- COOK: Cook food to the right temperature.

- CHILL: Refrigerate food promptly.

For more information about meat and poultry grading, go to USDA's Agricultural Marketing Service (AMS) Web site at www.ams.usda.gov/

United States Department of Agriculture

Summary of Federal Inspection Requirements for Meat Products

Source: https://www.fsis.usda.gov/wps/wcm/co...df?MOD=AJPERES

The Food Safety Inspection Service (FSIS ) is the public health agency in the U.S. Departmentof Agriculture responsible for ensuring that the Nation’s commercial supply of meat, poultry, and egg products is safe, wholesome, and correctly labeled and packaged.

Retail/Restaurant/Central Kitchen Exemption(9 CFR 303.1(f)(iv)(a)(6)).

Operations traditionally and usually conducted at retail stores, restaurants, and retail-type establishments that offer meat and meat food products for sale or service to household consumers generally are exempt from mandatory inspection. Only inspected and passed meat and meat food products (those bearing a mark of inspection) may be used in the preparation of products sold (including meals) at retail stores or restaurants. Sales must be in normal retailquantities, and certain Federal requirements apply (e.g., safe handling labels are required for raw product). Retail stores may prepare product for sale to other than household consumers (i.e., hotels, restaurants, or similar institutions (HRI)), but such HRI sales are limited to the annual dollar value or percentage of total retail sales specified by FSIS regulations. HRI sales also are limited by regulation to certain kinds of products (9 CFR 303.1(d) (2)).

Under certain conditions, products may be prepared at a restaurant central kitchen for sale in another facility without the benefit of inspection. To qualify, such products must be ready-to-eat when they leave the facility and safely transported under strict temperature controls to the destination restaurant where the product will be reheated and served to the end consumer. Product prepared at a central kitchen may only be transported to and prepared by restaurants under the same ownership. Operations exempt from inspection under the FMIA may be regulated and inspected under State and local laws.

Federal Inspection (21 U.S.C. 601, et seq.).

The Federal Meat Inspection Act (FMIA) requires that all meat sold commercially be inspected and passed to ensure that it is safe, wholesome, and properly labeled. The USDA Food Safety and Inspection Service (FSIS) is responsible for providing this inspection. The FMIA requires inspection for any product intended for human consumption, wholly or in part, from the carcass or parts of any cattle, sheep, swine, and goat. These animals, defined as “livestock” in the regulations, must be slaughtered and processed under Federal inspection, and the meat food products must be inspected and passed for human consumption. Food products from animals not subject to inspection under the FMIA (non-amenable species) are subject to regulation by U.S. Food and Drug Administration (FDA) and State and local authorities. Federal inspection personnel must be present at all times during livestock slaughter operations and for at least part of each shift during which there is further processing of meat products. In slaughter plants, inspection personnel verify the humane handling of animals and conduct ante-mortem inspection to ensure that the live animal is fit for slaughter. These inspection personnel also conduct post-mortem inspection to ensure that the meat from the carcass and internal organs are fit for human food. When meat is distributed to other federally inspected establishments for further processing, the product is inspected to ensure that the product is safe, wholesome, and correctly labeled and packaged. Inspected establishments must maintain and follow written Sanitation Standard Operating Procedures (SSOP) and Hazard Analysis and Critical Control Point (HACCP) plans.

In addition to inspecting the meat products, inspection personnel inspect the facilities and equipment to ensure sanitary conditions are maintained. FSIS also reviews records to ensure they accurately document establishment verification that the meat food products are in compliance with all applicable requirements.

State Inspection (21 U.S.C. 661).

Establishments that produce meat products sold entirely within a State require Federal inspection unless they are regulated under a State Meat and Poultry Inspection (MPI) program.

These State MPI programs are required to enforce requirements “at least equal to” those imposed under the Federal Acts.

State MPI programs certify annually, and FSIS reviews each State MPI program annually to determine whether each program meets the requisite “at least equal to” standard. As of September 2015, 27 States maintain cooperative agreements with FSIS to administer MPI programs, and FSIS reimburses a portion of the State’s operating costs. Exemptions: Certain meat products may be exempt from inspection requirements. However, they are still subject to the adulteration and misbranding provisions of the FMIA.

Personal/Individual Use Exemption (9 CFR 303.1(a)(1)).

Under certain conditions, a person may slaughter/ prepare livestock of his/her own raising for the exclusive use by him/her, members of his/her family, and his/her non-paying guests without the benefit of inspection. Absolutely no product produced under this exemption may be sold commercially.

Custom Exemption (9 CFR 303.1(a)(2)).

A custom-exempt establishment is one that slaughters and prepares livestock belonging to someone else for the exclusive use of that person. The custom-exempt facility provides a service for the livestock owner; it is not producing commercial product.

Custom-exempt facilities are exempt from the FMIA requirements for carcass-by-carcass inspections and the daily presence of inspectors during operations. Even so, the facility is not exempt from the adulteration, misbranding, and certain record-keeping provisions of those statutes.

Custom-exempt establishments are reviewed periodically to verify that facilities are maintained and operated in a manner that produces a safe, clean, and wholesome meat food product in a sanitary environment and are otherwise complying with the FMIA.

Ground Beef and Food Safety

Questions about "ground meat" or "hamburger" have always been in the top five food topics of calls to the USDA's Meat and Poultry Hotline. Here are the most frequently asked questions and information about why ground beef requires careful handling.

What's the difference between "hamburger" and "ground beef"?

Beef fat may be added to "hamburger," but not "ground beef." A maximum of 30% fat is allowed in either hamburger or ground beef. Both hamburger and ground beef can have seasonings, but no water, phosphates, extenders, or binders added. The labeling of meat food products must comply with the Federal Meat Inspection Act (FMIA) and the meat inspection regulations and labeling policies.

Most states and cities set standards for store-packaged ground beef which, by law, cannot be less than Federal standards. If products in retail stores were found to contain more than 30% fat, they would be considered "misbranded" under Federal law.

Is ground beef inspected and graded?

All meat transported and sold in interstate commerce must be federally inspected. The U.S. Department of Agriculture's (USDA) Food Safety and Inspection Service (FSIS) carries out USDA's responsibilities under the Federal Meat Inspection Act. These laws protect consumers by ensuring that meat products are wholesome, unadulterated, and correctly labeled and packaged.

Many states have their own inspection programs that are applicable for meats produced and sold within their borders only. State inspection programs must enforce requirements at least equal to those of Federal inspection laws.

Ground beef exported to the U.S. from USDA-approved eligible nations must meet all safety standards applied to foods produced in the United States. They must employ equivalent sanitary measures that provide the same level of protection against food hazards as is achieved domestically.

Grades are assigned as a standard of quality only. It is voluntary for a company to hire a Federal Grader to certify the quality of its product. Beef grades are USDA Prime, Choice, Select, Standard, Commercial, Utility, Cutter, and Canner. They are set by the USDA Agricultural Marketing Service. Most ground beef is not graded.

What kind of bacteria can be in ground beef? Are they dangerous?

Bacteria are everywhere in our environment; virtually any food can harbor bacteria. In foods of animal origin, pathogenic (illness-causing) bacteria, such as Salmonella, Shiga-toxin producing Escherichia coli (STECs), Campylobacter jejuni, Listeria monocytogenes, and Staphylococcus aureus, cause illness. These harmful bacteria cannot be seen or smelled.

If the pathogens are present when meat is ground, then more of the meat surface is exposed to the harmful bacteria. Also, grinding allows any bacteria present on the surface to be mixed throughout the meat. Bacteria multiply rapidly in the "Danger Zone" — temperatures between 40 and 140 °F (4.4 and 60 °C). To keep bacterial levels low, store ground beef at 40 °F (4.4 °C) below and use within 2 days, or freeze. To destroy harmful bacteria, cook ground beef to a safe minimum internal temperature of 160 °F (71.1 °C).

Other bacteria cause spoilage. Spoilage bacteria generally are not harmful, but they will cause food to deteriorate or lose quality by developing a bad odor or feeling sticky on the outside.

Why is the E. coli O157:H7 bacterium of special concern in ground beef?

E. coli O157:H7 is the most well-known Shiga toxin-producing E. coli (STEC), though other STEC strains have also been identified. STECs produce large quantities of a potent toxin that forms in the intestine and causes severe damage to the lining of the intestine. This causes a disease called hemorrhagic colitis, and may also cause Hemolytic Uremic Syndrome, particularly in young children. STECs can colonize in the intestines of animals, which could contaminate muscle meat at slaughter.

E. coli O157:H7 bacteria survive refrigerator and freezer temperatures. Once they get in food, they can multiply very slowly at temperatures as low as 44 °F (6.7 °C). While the actual infectious dose is unknown, most scientists believe it takes only a small number of this strain of E. coli to cause serious illness and even death, especially in children and older adults. The bacteria are killed by thorough cooking, which for ground beef is an internal temperature of 160 °F (71.1 °C) as measured by a food thermometer.

Illnesses caused by E. coli O157:H7 have been linked with the consumption of undercooked ground beef. Other foods, including raw milk, apple cider, dry cured sausage, fresh produce, and undercooked roast beef, also have been implicated.

How is beef treated in a USDA-inspected plant to reduce bacteria?

The following methods have been extensively studied and found effective in reducing bacterial contamination on a beef carcass: organic acid washes, water washes, steam pasteurization, steam vacuuming, and other antimicrobials.

Why is ground beef produced in a USDA-inspected plant safer than beef ground in a store or at home?

Hearing about recalls of ground beef products contaminated with E. coli O157:H7 or Salmonella might cause some consumers to consider grinding beef at home; however, this is not a safer alternative to purchasing ground beef at a retail store. In fact, USDA cautions against grinding beef at home.

In a USDA-inspected plant, trimmed beef destined for grinding is tested for the presence of E. coli. However, primal cuts, such as steaks and roasts, are usually not tested. When stores or consumers grind these primal cuts, it's possible that pathogens may be present on the raw beef, and neither you nor meat market employees can see, smell, or taste dangerous bacteria. In addition, USDA-inspected plants have Sanitation Standard Operating Procedures that cover policies such as the cleaning of grinding machines and the handling and chilling of ground beef. Consumers and stores might not follow such stringent sanitary procedures.

How do you know if ground beef sold in a store is from a USDA-inspected establishment?

Ground beef produced at a USDA-inspected plant will have a USDA establishment number on the package, written as "EST." (for "establishment") followed by a number. Much of the ground beef sold in stores today are ground in a USDA-inspected plant; sometimes the store will print the establishment number on its packaging. If you don't see an "EST." number, ask the store about its source for ground beef.

Why are there recalls of ground beef?

Live cattle can harbor various bacteria, including Shiga toxin-producing E. coli (STEC) and Salmonella. In 1994, the USDA declared E. coli O157:H7 as an adulterant in ground beef. In 2012, USDA declared six additional most common STECs as adulterants in raw ground beef as well. Before 1996, the inspection of beef carcasses was by sight, touch, and smell. With the passage of the 1996 Final Rule on Pathogen Reduction; Hazard Analysis and Critical Control Point (PR/HACCP) Systems, FSIS began requiring microbial testing in slaughter plants for E. coli. If E. coli O157:H7 is detected, recalls are initiated by the manufacturer or distributor of the meat, sometimes at the request of FSIS.

From what cuts of beef are ground beef and hamburger made?

Generally, ground beef is made from the less tender and less popular cuts of beef. Trimmings from more tender cuts may also be used. Grinding tenderizes the meat and the fat reduces its dryness and improves flavor.

What is the significance of the "Sell-By" date on the package?

"Sell-By" dates are a guide for retailers. Although many products bear "Sell-By" dates, product dating is not a Federal requirement. While these dates are helpful to the retailer, they are reliable only if the food has been kept at a safe temperature during storage and handling. USDA suggests that consumers cook or freeze ground beef within 2 days after purchase for maximum quality.

What is the safe food handling label on ground beef packages?

A safe food handling label should be on all raw or partially precooked (not ready-to-eat) meat and poultry packages. The label tells the consumer how to safely store, prepare, and handle raw meat and poultry products in the home.

What is the Country of Origin Label on ground beef packages?

The Country of Origin Label (COOL) is not a food safety issue. It is a law requiring that package labels of certain foods bear the names of the country or countries where the food came from. FSIS enforces the labeling of ground beef.

To find information about COOL, go to http://www.ams.usda.gov/AMSv1.0/cool

If you have a food labeling complaint about a country of origin, send your complaint to:

Country of Origin Labeling Division

USDA-AMS

Room 2620-S, Stop 0216

1400 Independence Avenue, SW

Washington, DC 20250-0216

Email: Cool@ams.usda.gov

Can bacteria spread from one surface to another?

Yes. It is called cross-contamination. Bacteria in raw meat juices can contaminate foods that have been cooked safely or raw foods that won't be cooked, such as salad ingredients. Bacteria also can be present on equipment, hands, and even in the air.

To avoid cross-contamination, wash your hands with soap and warm water for at least 20 seconds before and after handling ground beef to make sure you don't spread bacteria. Don't reuse any packaging materials. Use soap and hot water to wash utensils and surfaces which have come into contact with the raw meat. Utensils and surfaces can be sanitized with a solution of 1 tablespoon of unscented, liquid chlorine bleach per gallon of water. Don't put cooked hamburgers on the same platter that held the raw patties or use utensils that touched the raw meat unless you wash the platter or utensils first.

What's the best way to handle raw ground beef when shopping?

At the store, choose a package that feels cold and is not torn. If possible, place the package in a plastic bag so leaking juices won't drip on other foods. Make ground beef one of the last items to go into your shopping cart. Separate raw meat from ready-cooked items in your cart. Have the clerk place the raw ground beef in a separate bag.

Plan to drive directly home from the grocery store. You may want to bring a cooler with ice for perishables.

How should raw ground beef be stored at home?

Refrigerate or freeze ground beef as soon as possible after purchase. This preserves freshness and slows the growth of bacteria. It can be refrigerated or frozen in its original packaging if the meat will be used soon.

If refrigerated, keep at 40 °F (4.4 °C) or below and use within 1 or 2 days.

For longer freezer storage, wrap in heavy duty plastic wrap, aluminum foil, freezer paper, or plastic bags made for freezing. Ground beef is safe indefinitely if kept frozen, but will lose quality over time. It is best if used within 4 months. Mark your packages with the date they were placed in the freezer so you can keep track of storage times.

What is the best way to thaw ground beef?

The best way to safely thaw ground beef is in the refrigerator. Keeping meat cold while it is defrosting is essential to prevent the growth of bacteria. Cook or refreeze within 1 or 2 days.

To defrost ground beef more rapidly, you can defrost in the microwave oven or in cold water. If using the microwave, cook the ground beef immediately because some areas may begin to cook during the defrosting. To defrost in cold water, put the meat in a watertight plastic bag and submerge. Change the water every 30 minutes. Cook immediately. Do not refreeze raw ground meat thawed in cold water or in the microwave oven unless you cook it first.

Never leave ground beef or any perishable food out at room temperature for more than 2 hours (1 hour at 90 °F and above).

The Color of Meat and Poultry

Source: https://www.fsis.usda.gov/wps/portal...education/get-

answers/food-safety-fact-sheets/meat-preparation/the-color-of-meat-and-poultry/the-color-of-

meat-and-poultry/ct_index

Color is important when meat and poultry are purchased, stored, and cooked. Often an attractive, bright color is a consideration for the purchase. So, why are there differences in the color and what do they mean? Listed below are some questions and answers to help you understand the color differences.

- What factors affect the color of meat and poultry?

Myoglobin, a protein, is responsible for the majority of the red color. Myoglobin doesn't circulate in the blood but is fixed in the tissue cells and is purplish in color. When it is mixed with oxygen, it becomes oxymyoglobin and produces a bright red color. The remaining color comes from the hemoglobin which occurs mainly in the circulating blood, but a small amount can be found in the tissues after slaughter.

Color is also influenced by the age of the animal, the species, sex, diet, and even the exercise it gets. The meat from older animals will be darker in color because the myoglobin level increases with age. Exercised muscles are always darker in color, which means the same animal can have

variations of color in its muscles.

In addition, the color of meat and poultry can change as it is being stored at retail and in the home (see explanation in question 5). When safely stored in the refrigerator or freezer, color changes are normal for fresh meat and poultry.

- Does a change in color indicate spoilage?

Change in color alone does not mean the product is spoiled. Color changes are normal for fresh product. With spoilage there can be a change in color—often a fading or darkening. In addition to the color change, the meat or poultry will have an off odor, be sticky or tacky to the touch, or it may be slimy. If meat has developed these characteristics, it should not be used.

- If the color of meat and poultry changes while frozen, is it safe?

Color changes, while meat and poultry are frozen, occur just as they do in the refrigerator. Fading and darkening, for example, do not affect their safety. These changes are minimized by using freezer-type wrapping and by expelling as much air as possible from the package.

- What are the white dried patches on frozen meat and poultry?

The white dried patches indicate freezer burn. When meat and poultry have been frozen for an extended period of time or have not been wrapped and sealed properly, this will occur. The product remains safe to eat, but the areas with freezer burn will be dried out and tasteless and can be trimmed away if desired.

THE COLOR OF MEAT

- When displayed at the grocery store, why is some meat bright red and other meat very dark in color?

Optimum surface color of fresh meat (i.e., cherry-red for beef; dark cherry-red for lamb; grayish- pink for pork; and pale pink for veal) is highly unstable and short-lived. When meat is fresh and protected from contact with air (such as in vacuum packages), it has the purple-red color that comes from myoglobin, one of the two key pigments responsible for the color of meat. When exposed to air, myoglobin forms the pigment, oxymyoglobin, which gives meat a pleasingly cherry-red color. The use of a plastic wrap that allows oxygen to pass through it helps ensure that the cut meats will retain this bright red color. However, exposure to store lighting as well as the continued contact of myoglobin and oxymyoglobin with oxygen leads to the formation of metmyoglobin, a pigment that turns meat brownish-red. This color change alone does not mean the product is spoiled (see explanation in question 2).

- Why is pre-packaged ground beef red on the outside and sometimes grayish-brown on the inside?

These color differences do not indicate that the meat is spoiled or old. As discussed earlier, fresh cut meat is purplish in color. Oxygen from the air reacts with meat pigments to form a bright red color which is usually seen on the surface of ground beef purchased in the supermarket. The interior of the meat may be grayish-brown due to the lack of oxygen penetrating below the surface.

- A beef roast has darkened in the refrigerator, is it safe?

Yes, it is safe. The darkening is due to oxidation, the chemical changes in myoglobin due to the oxygen content. This is a normal change during refrigerator storage.

- Can cooked ground beef still be pink inside?

Yes, ground beef can be pink inside after it is safely cooked. The pink color can be due to a reaction between the oven heat and myoglobin, which causes a red or pink color. It can also occur when vegetables containing nitrites are cooked along with the meat. Because doneness and safety cannot be judged by color, it is very important to use a food thermometer when cooking ground beef. To be sure all harmful bacteria are destroyed, cook raw ground beef to an internal temperature of 160 °F as measured with a food thermometer.

- What causes iridescent colors on meats?

Meat contains iron, fat, and other compounds. When light hits a slice of meat, it splits into colors like a rainbow. There are various pigments in meat compounds that can give it an iridescent or greenish cast when exposed to heat and processing. Wrapping the meat in airtight packages and storing it away from light will help prevent this situation. Iridescence does not represent decreased quality or safety of the meat.

- What causes grayish or green color on cured meats?

Exposure to light and oxygen causes oxidation to take place, which causes the breaking down of color pigments formed during the curing process. Chemicals in the cure and oxygen, as well as energy from ultraviolet and visible light, contribute to both the chemical breakdown and microbial spoilage of the product. Cure, such as nitrite, chemically changes the color of muscle. Curing solutions are colored in order to distinguish them from other ingredients (such as sugar or salt) used in fresh and cured meat products. For example, cured raw pork is gray, but cured cooked pork (e.g., ham) is light pink.

THE COLOR OF POULTRY

- What is the usual color of raw poultry?

Raw poultry can vary from a bluish-white to yellow. All of these colors are normal and are a direct result of breed, exercise, age, and/or diet. Younger poultry has less fat under the skin, which can cause the bluish cast, and the yellow skin could be a result of marigolds in the feed.

- What causes the differences in color of raw ground poultry?

Ground poultry varies in color according to the part being ground. Darker pink means more dark meat was used and a lighter pink means more white meat was included (or skin was included). Ground poultry can contain only muscle meat and skin with attached fat in proportion to the whole bird.

- What causes dark bones in cooked poultry?

Darkening of bones and meat around the bones occurs primarily in young (6-8 weeks) broiler- fryer chickens. Since the bones have not calcified or hardened completely, pigment from the bone marrow seeps through the bones and into the surrounding area. Freezing can also contribute to this darkening. This is an aesthetic issue and not a safety one. The meat is safe to eat when all parts have reached a safe minimum internal temperature of 165 °F as measured with a food thermometer.

- What color is safely cooked poultry?

Safely cooked poultry can vary in color from white to pink to tan. For safety when cooking poultry, use a food thermometer to check the internal temperature. For a whole chicken or turkey, check the internal temperature in the innermost part of the thigh and wing and the thickest part of the breast. All the meat—including any that remains pink—is safe to eat as soon as all parts reach at least 165 °F as measured with a food thermometer.

- Why is some cooked poultry pink?

Chemical changes occur during cooking. Oven gases in a heated gas or electric oven react chemically with hemoglobin in the meat tissues to give it a pink tinge. Often meat of younger birds shows the most pink because their thinner skins permit oven gases to reach the flesh. Older animals have a fat layer under their skin, giving the flesh added protection from the gases. Older poultry may be pink in spots where fat is absent from the skin. Also, nitrates and nitrites, which are often used as preservatives or may occur naturally in the feed or water supply used, can cause a pink color.

- If fully cooked smoked poultry is pink, is it safe?

Poultry grilled or smoked outdoors can be pink, even when all parts have attained temperatures well above 165 °F as measured with a food thermometer. There may be a pink-colored rim about one-half inch wide around the outside of the cooked product. Commercially prepared, smoked poultry is usually pink because it is prepared with natural smoke and liquid smoke flavor.

What is beef?

Source: https://www.fsis.usda.gov/wps/portal...education/get- answers/food-safety-fact-sheets/meat-preparation/beef-from-farm-to-table/ct_index/!ut/p/a1/jZDBbsIwDIafZQ9gOaWAxhFVmmgHrRCCZbkgA06JRJMqtbaxp1-3nTYNhn2y_P2y9aFBjcbTi6tJXPB0-pzNeKuWapxMMlVUk-RB5eVmWT1mmbpfjXrg-QpQpjfmL9RU_ZcvbjgwiItsUaNpSY7gvA2oaxYg371y7FDbEA7QkWU5g6W9QHdkln7RMAm0kVuKX0JQ75gt2BiaHowNSACh3YlR72Xr_IHf8AnNz5dU0ndepqvhrChTVQ1_A384-wYuS2mbtX6fT2fK5XcfPTfBRA!!/#1

The domestication of cattle for food dates to about 6500 B.C. in the Middle East. Cattle were not native to America, but brought to the New World on ships by European colonists. Americans weren't big eaters of fresh beef until about 1870, due to the enormous growth of the cattle industry in the West. The introduction of cattle cars and refrigerated cars on the railroad facilitated distribution of the beef.

"Beef" is meat from full-grown cattle about 2 years old. A live steer weighs about 1,000 pounds and yields about 450 pounds of edible meat. There are at least 50 breeds of beef cattle, but fewer than 10 make up most cattle produced. Some major breeds are Angus, Hereford, Charolaise, and Brahman.

"Baby beef" and "calf" are 2 interchangeable terms used to describe young cattle weighing about 700 pounds that have been raised mainly on milk and grass. The meat cuts from baby beef are smaller; the meat is light red and contains less fat than beef. The fat may have a yellow tint due to the vitamin A in grass.

"Veal" is meat from a calf which weighs about 150 pounds. Those that are mainly milk-fed usually are less than 3 months old. The difference between "veal" and "calf" is based on the color of their meat, which is determined almost entirely by diet. Veal is pale pink and contains more cholesterol than beef.

NOTE: This information is about whole muscle beef and variety beef. See “Ground Beef and Food Safety" for information about hamburger and ground beef.

How are cattle raised?

All cattle start out eating grass; three-fourths of them are "finished" (grown to maturity) in feedlots where they are fed specially formulated feed based on corn or other grains.

Can hormones & antibiotics be used in cattle raising?

Antibiotics may be given to prevent or treat disease in cattle. A "withdrawal" period is required from the time antibiotics are administered until it is legal to slaughter the animal. This is so residues can exit the animal's system. FSIS randomly samples cattle at slaughter and tests for residues. Data from this Monitoring Plan have shown a very low percentage of residue violations. Not all antibiotics are approved for use in all classes of cattle. However, if there is a demonstrated therapeutic need, a veterinarian may prescribe an antibiotic that is approved in other classes for an animal in a non-approved class. In this case, no detectable residues of this drug may be present in the edible tissues of the animal at slaughter.

Hormones may be used to promote efficient growth. Estradiol, progesterone, and testosterone (three natural hormones), and zeranol and trenbolone acetate (two synthetic hormones) may be used as an implant on the animal's ear. The hormone is time released, and is effective for 90 to 120 days. In addition, melengesterol acetate, which can be used to suppress estrus, or improve weight gain and feed efficiency, is approved for use as a feed additive. Not all combinations of hormones are approved for use in all classes of cattle. Hormones are approved for specific classes of animals only, and cannot be used in non-approved classes.

How is beef inspected?

Inspection is mandatory; grading is voluntary, and a plant pays to have its meat graded. USDA- graded beef sold at the retail level is Prime, Choice, and Select. Lower grades (Standard, Commercial, Utility, Cutter, and Canner) are mainly ground or used in processed meat products. Retail stores may use other terms which must be different from USDA grades.

USDA Prime beef (about two percent of graded beef) has more marbling, so it is the most tender and flavorful. However, it is higher in fat content. Most of the graded beef sold in supermarkets is USDA Choice or USDA Select. The protein, vitamin, and mineral content of beef are similar regardless of the grade.

What is the “USDA Certified Tender” and “USDA Certified Very Tender” Program?

USDA Certified Tender Shield In connection with the USDA Beef Carcass Quality Grading Program under the Agricultural Marketing Service (AMS) and grades such as USDA Prime, Choice and Select, this program provides retailers with a new tool to help their customers identify what specific cuts of beef are consistently tender or very tender.

Companies wishing to use this designation must meet the International tenderness standard and be reviewed by AMS’ Grading and Verification Division prior to final use by the approved program. Once the program has been approved, USDA’s Food Safety and Inspection Service (FSIS), Office of Policy and Program Development (OPPD), Labeling and Program Delivery Division (LPDD) must also approve label claims for “USDA Tender” or “USDA Very Tender”. For more information, go to http://www.ams.usda.gov/AMSv1.0/Tend...MarketingClaim.

How is ungraded beef different?

All beef is inspected for wholesomeness. The overall quality of ungraded beef may be higher or lower than most government grades found in retail markets.

What is marbling?

Marbling is white flecks of fat within the meat muscle. The greater amount of marbling in beef, the higher the grade because marbling makes beef more tender, flavorful, and juicy.

Retail Cuts of Fresh Beef

There are four basic major (primal) cuts into which beef is separated: chuck, loin, rib, and round. It is recommended that packages of fresh beef purchased in the supermarket be labeled with the primal cut as well as the product, such as "chuck roast" or "round steak." This helps consumers know what type of heat is best for cooking the product. Generally, chuck and round are less tender and require moist heat such as braising; loin and rib can be cooked by dry heat methods such as broiling or grilling.

Unfortunately, names for various cuts can vary regionally in stores, causing confusion over the choice of cooking method. For example, a boneless top loin steak is variously called: strip steak, Kansas City Steak, N.Y. strip steak, hotel cut strip steak, ambassador steak, or club sirloin steak.

How much beef is consumed?

Figures from the USDA's Economic Research Service show average annual per capita beef consumption for the following selected periods:

How much Beef is Consumed?

| Year | Weight | Year | Weight |

|---|---|---|---|

| 1910 | 48 pounds | 1960 | 59 pounds |

| 1920 | 41 pounds | 1970 | 80 pounds |

| 1930 | 34 pounds | 1980 | 72 pounds |

| 1940 | 38 pounds | 1990 | 64 pounds |

| 1950 | 45 pounds | 2012 | 54.5 pounds |

Nutrition Labeling

Nutrition claims such as "lean" and "extra lean" are sometimes seen on beef products. Here are their definitions:

- "Lean" - 100 grams of beef with less than 10 grams of fat, 4.5 grams or less of saturated fat, and

- "Extra Lean" - 100 grams of beef with less than 5 grams of fat, less than 2 grams of saturated fat, and less than 95 milligrams of cholesterol. less than 95 milligrams of cholesterol.

What does "natural" mean?

All fresh meat qualifies as "natural." Products labeled "natural" cannot contain any artificial flavor or flavoring, coloring ingredient, chemical preservative, or any other artificial or synthetic ingredient; and the product and its ingredients are not more than minimally processed (ground, for example). All products claiming to be natural should be accompanied by a brief statement which explains what is meant by the term "natural."

Some companies promote their beef as "natural" because they claim their cattle weren't exposed to antibiotics or hormones and were totally raised on a range instead of being "finished" in a feedlot.

How & why is some beef aged?

Beef is aged to develop additional tenderness and flavor. It is done commercially under controlled temperatures and humidity. Since aging can take from 10 days to 6 weeks, USDA does not recommend aging beef in a home refrigerator.

Why beef is called a "red" meat?

Oxygen is delivered to muscles by the red cells in the blood. One of the proteins in meat, myoglobin, holds the oxygen in the muscle. The amount of myoglobin in animal muscles determines the color of meat. Beef is called a "red" meat because it contains more myoglobin than chicken or fish. Other "red" meats are veal, lamb, and pork.

Color of Beef

Beef muscle meat not exposed to oxygen (in vacuum packaging, for example) is a burgundy or purplish color. After exposure to the air for 15 minutes or so, the myoglobin receives oxygen and the meat turns bright, cherry red.

After beef has been refrigerated about 5 days, it may turn brown due to chemical changes in the myoglobin. Beef that has turned brown during extended storage may be spoiled, have an off- odor, and be tacky to the touch.

Iridescent Color of Roast Beef

Sliced cooked beef or lunch meat can have an iridescent color. Meat contains iron, fat, and many other compounds. When light hits a slice of meat, it splits into colors like a rainbow. There are also various pigments in meat compounds which can give it an iridescent or greenish cast when exposed to heat and processing. Iridescent beef isn't spoiled necessarily. Spoiled cooked beef would probably also be slimy or sticky and have an off-odor.

Additives

Additives are not allowed on fresh beef. If beef is processed, additives such as MSG, salt, or sodium erythorbate must be listed on the label.

Dating of Beef Products

Product dating is not required by Federal regulations. However, many stores and processors may voluntarily date packages of raw beef or processed beef products. If a calendar date is shown, there must be a phrase explaining the meaning of the date.

Use or freeze products with a "Sell-By" date within 3 to 5 days of purchase.

If the manufacturer has determined a "Use-By" date, observe it. This is a quality assurance date after which peak quality begins to lessen but the product may still be used. It's always best to buy a product before its date expires. It's not important if a date expires after freezing beef because all foods stay safe while properly frozen.

What foodborne organisms are associated with beef?

Escherichia coli can colonize in the intestines of animals, which could contaminate muscle meat at slaughter. E. coli O157:H7 is a rare strain that produces large quantities of a potent toxin that forms in and causes severe damage to the lining of the intestine. The disease produced by it is called Hemorrhagic Colitis and is characterized by bloody diarrhea. E. coli O157:H7 is easily destroyed by thorough cooking.

Salmonella may be found in the intestinal tracts of livestock, poultry, dogs, cats, and other warm- blooded animals. There are about 2,000 Salmonella bacterial species. Freezing doesn't kill this microorganism, but it is destroyed by thorough cooking. Salmonella must be eaten to cause illness. They cannot enter the body through a skin cut. Cross-contamination can occur if raw meat or its juices contact cooked food or foods that will be eaten raw, such as salad.

Staphylococcus aureus can be carried on human hands, nasal passages, or throats. Most foodborne illness outbreaks are a result of contamination from food handlers and production of a heat-stable toxin in the food. Sanitary food handling and proper cooking and refrigerating should prevent staphylococcal foodborne illness.

Listeria monocytogenes is destroyed by cooking, but a cooked product can be recontaminated by poor handling practices and poor sanitation. FSIS has a zero tolerance for Listeria monocytogenes in cooked and ready-to-eat products such as beef franks or lunchmeat. Observe handling information such as "Keep Refrigerated" and "Use-By" dates on labels.

Rinsing Beef

It isn't necessary to wash raw beef before cooking it. Any bacteria which might be present on the surface would be destroyed by cooking.

How to Handle Beef Safely

Raw Beef: Select beef just before checking out at the register. Put packages of raw beef in disposable plastic bags, if available, to contain any leakage which could cross-contaminate cooked foods or produce. Beef, a perishable product, is kept cold during store distribution to retard the growth of bacteria.

Take beef home immediately and refrigerate it at 40 °F (4.4 °C); use within 3 to 5 days—1 or 2 days for ground beef and variety meats such as liver, kidneys, tripe, sweetbreads, or tongue—or at freeze at 0 °F (-17.8 °C). If kept frozen continuously, it will be safe indefinitely.

It is safe to freeze beef in its original packaging or repackage it. However, for long-term freezing, overwrap the porous store plastic with aluminum foil, freezer paper, or freezer-weight plastic wrap or bags to prevent "freezer burn," which appears as grayish-brown leathery spots and is caused by air reaching the surface of food. Cut freezer-burned portions away either before or after cooking the beef. Heavily freezer-burned products may have to be discarded for quality reasons. For best quality, use steaks and roasts within 9 to 12 months.

Ready-Prepared Beef: For fully-cooked, take-out beef dishes such as Chinese food, barbecued ribs, or fast food hamburgers, be sure they are hot at pickup. Use cooked beef within 2 hours—1 hour if the air temperature is above 90 °F (32.2 °C) or refrigerate it at 40 °F (4.4 °C) in shallow, covered containers. Eat within 3 to 4 days, either cold or reheated to 165 °F (73.9 °C)--hot and steaming. It is safe to freeze ready-prepared beef dishes. For best quality, use within 4 months.

Safe Defrosting

There are three safe ways to defrost beef: in the refrigerator, in cold water, and in the microwave. Never defrost on the counter or in other locations.

Refrigerator: It's best to plan ahead for slow, safe thawing in the refrigerator. Ground beef, stew meat, and steaks may defrost within a day. Bone-in parts and whole roasts may take 2 days or longer. Once the raw beef defrosts, it will be safe in the refrigerator for 3 to 5 days before cooking. During this time, if you decide not to use the beef, you can safely refreeze it without cooking it first.

Cold Water: To defrost beef in cold water, do not remove packaging. Be sure the package is airtight or put it into a leak-proof bag. Submerge the beef in cold water, changing the water every 30 minutes so that it continues to thaw. Small packages of beef may defrost in an hour or less; a 3- to 4-pound roast may take 2 to 3 hours.

Microwave: When microwave defrosting beef, plan to cook it immediately after thawing because some areas of the food may become warm and begin to cook during microwaving. Holding partially-cooked food is not recommended because any bacteria present wouldn't have been destroyed.

Foods defrosted in the microwave or by the cold water method should be cooked before refreezing because they may have been held at temperatures above 40 °F (4.4 °C).

It is safe to cook frozen beef in the oven, on the stove, or grill without defrosting it first; the cooking time may be about 50% longer. Do not cook frozen beef in a slow cooker.

Marinating

Marinate beef in the refrigerator up to 5 days. Boil used marinade before brushing on cooked beef. Discard any uncooked leftover marinade.

Partial Cooking

Never brown or partially cook beef to refrigerate and finish cooking later because any bacteria present wouldn't have been destroyed. It is safe to partially pre-cook or microwave beef immediately before transferring it to the hot grill to finish cooking.

Liquid in Package

Many people think the red liquid in packaged fresh beef is blood. However, blood is removed from beef during slaughter and only a small amount remains within the muscle tissue. Since beef is about 3/4 water, this natural moisture combined with protein is the source of the liquid in the package.

Safe Cooking

For safety, the USDA recommends cooking hamburgers and ground beef mixtures such as meat loaf to 160 °F (71.1 °C) as measured with a food thermometer. Cook all organ and variety meats (such as heart, kidney, liver and tongue) to 160 °F (71.1 °C).

Cook all raw beef steaks and roasts to a minimum internal temperature of 145 °F (62.8 °C) as measured with a food thermometer before removing meat from the heat source. For safety and quality, allow meat to rest for at least three minutes before carving or consuming. For reasons of personal preference, consumers may choose to cook meat to higher temperatures.

For approximate cooking times for use in meal planning, see the following chart compiled from various resources. Times are based on beef at refrigerator temperature—40 °F (4.4 °C). Remember that appliances and outdoor grills can vary in heat. Use a food thermometer to check for safe cooking and doneness of beef.

| Type of Beef | Size | Cooking Method | Cooking Time | Internal Temperature |

| Rib Roast (bone in) | 4 to 6 lbs. | Roast 325 °F | 23-25 min/lb | 145 °F (62.8 °C) rest > 3 minutes |

| Rib Roast (boneless rolled) | 4 to 6 lbs. | Roast 325 °F | Add 5-8 min/lb to times above | |

| Chuck Roast, Brisket | 3 to 4 lbs. | *Braise 325 °F | *Braise 325 °F | |

| Round or Rump Roast | 2 1/2 to 4 lbs. | Roast 325 °F | 30-35 min/lb | |

| Tenderloin (whole) | 4 to 6 lbs. | Roast 425 °F | 45-60 min total | |

| Steaks | 3/4" thick | Broil/Grill | 4-5 min per side | |

| Stew or Shank Cross Cuts | 1 to 1 1/2" thick | Cover with liquid; | simmer 2 to 3 hours | |

| Short Ribs | 4" long and 2" thick | *Braise 325 °F | 1 1/2 to 2 1/2 hours | |

| Hamburger Patties (fresh) | 4 ounces | Grill, Broil or Fry | 3 to 5 min/side | 160 °F (71.1 °C) |

*Braising is roasting or simmering less-tender meats with a small amount of liquid in a tightly covered pan

Microwave Directions:

- When microwaving unequal size pieces of beef, arrange in dish or on rack so thick parts are toward the outside of dish and thin parts are in the center; cook on medium-high or medium power.

- Place a roast in an oven cooking bag or in a covered pot.

- Refer to the manufacturer's directions that accompany the microwave oven for suggested cooking times.

- Use a meat thermometer to test for doneness in several places to be sure temperatures listed above have been reached.

Storage Times

Since product dates aren't a guide for safe use of a product, how long can the consumer store the food and still use it at top quality? Follow these tips:

- Purchase the product before the date expires

- Follow handling recommendations on product.

- Keep beef in its package until using.

- It is safe to freeze beef in its original packaging. If freezing longer than 2 months, over wrap these packages with airtight heavy-duty foil, plastic wrap, or freezer paper or place the package inside a plastic bag.

- For storage times, consult the following chart. Home Storage of Beef Products

Home Storage of Beef Products

If product has a "Use-By" Date, follow that date. If product has a "Sell-By" Date or no date, cook or freeze the product by the times on the following chart

| Storage times for Beef Products | Refridgerator 40 °F (4.4 °C) | Freezer 0 °F (-17.8 °C) |

|---|---|---|

| Fresh beef roast, steaks, chops or ribs | 3 to 5 days | 6 to 12 months |

| Fresh bee liver or variety meats | 1 or 2 days | 3 to 4 months |

| Home cooked beef, soups, stews or casseroles | 3 to 4 days | 2 to 3 months |

| Store-cooked convenience meals | 1 to 2 days | 2 to 3 months |

| Cooked beef gravy or beef broth | 1 or 2 days | 2 to 3 months |

| Beef hot dogs or lunch meats, sealed in package | 2 weeks (or 1 week after a "Use-By" date) | 1 to 2 months |

| Beef hot dogs, opened package | 7 days | 1 to 2 months |

| Lunch meats, opened package | 3 to 5 days | 1 to 2 months |

| TV dinners, frozen casseroles | Keep Frozen | 3 to 4 months |

| Canned beef products in pantry | 2 to 5 years in pantry; 3 to 4 days after opening | After opening, 2 to 3 months |

| Jerky, commercially vacuum packaged | 1 year in pantry Refridgerate 2 to 3 months | Do not freeze |